Flow Rate Transmitter is ideal for batching, industrial process control, mobile hydraulic equipment and computer / PLC controlled hydraulic system monitoring application. Available in analog or pulse outputs.

The Flow Rate Transmitter is ideal for batching, industrial process control, mobile hydraulic equipment and computer / PLC controlled hydraulic system monitoring applications. It is designed without delicate internal components to break, abrade, or corrode. The weather tight construction includes a rugged cast aluminum enclosure built to NEMA 4X standard for installation outdoors. This variable area flow meter is used to measure air, gas, oil, and water. The transmitter provides a visual indication of flow rate that matches the transmitted output for direct reading.

Key features

-

Measuring Accuracy:±2.0% of full scale (oil & water)

-

14 Flow Ranges:0.1 to 150 GPM (0.5-550 LPM), 2-1300 SCFM (1-600 SLPS)

-

Pressure Rating:Liquid: up to 6000 PSIG (410 bar), Air/Gas: 1000 PSIG (69 bar)

-

Temperature Rating:Media: 185°F (85°C) Ambient: 185°F (85°C)

- Description

- Technical Specifications

- Electronics

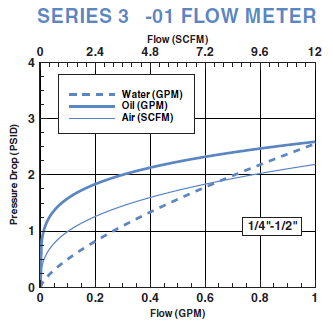

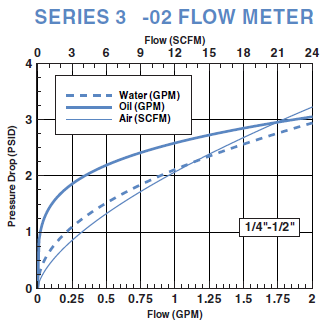

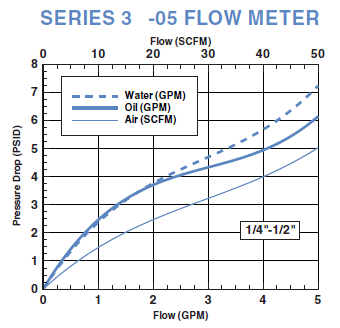

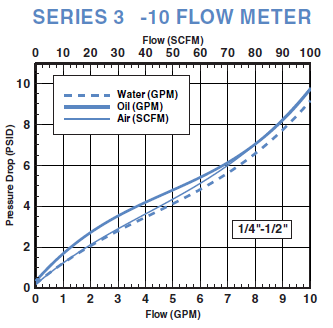

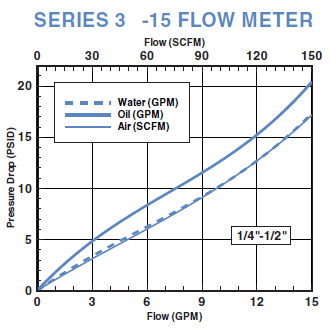

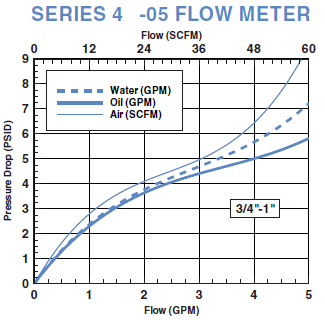

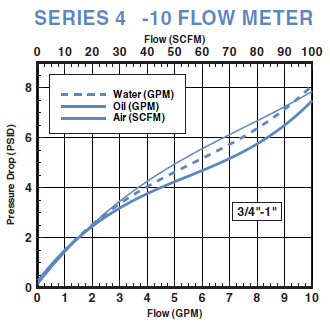

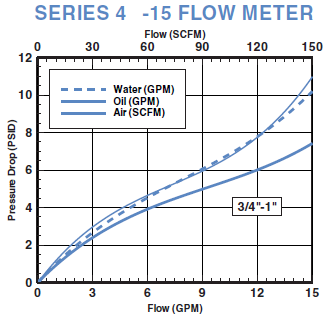

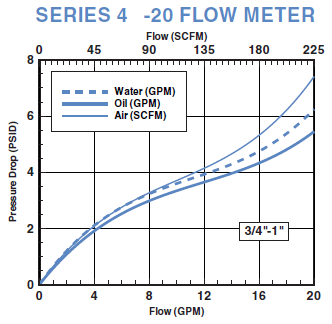

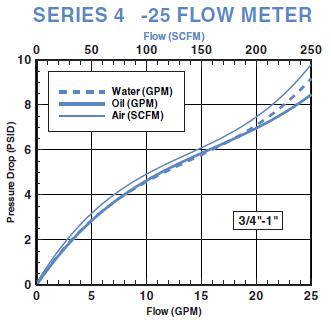

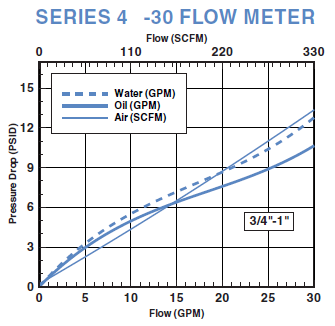

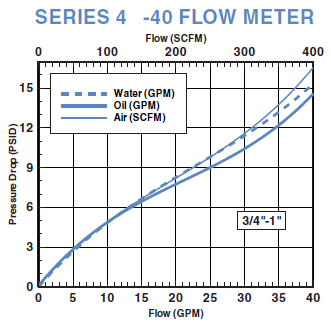

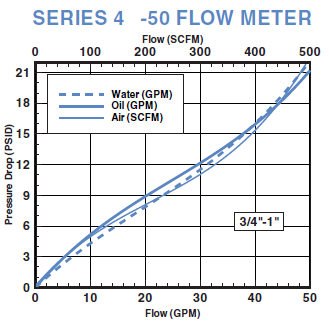

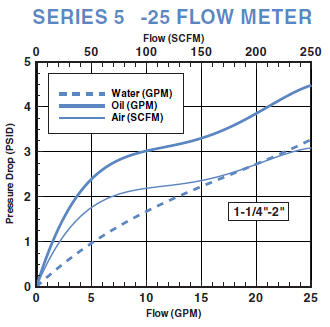

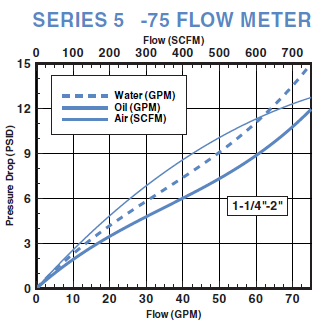

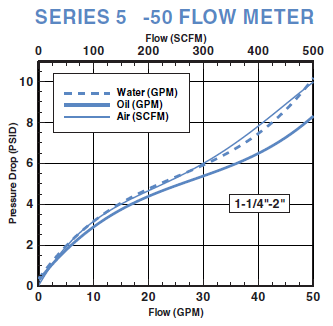

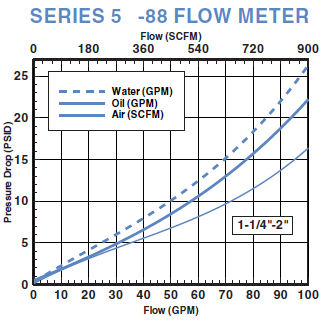

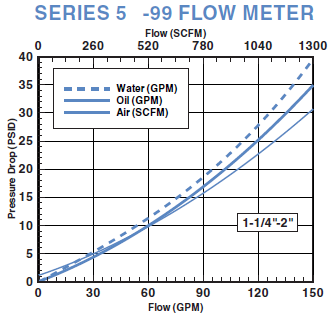

- Pressure Differential Graphs

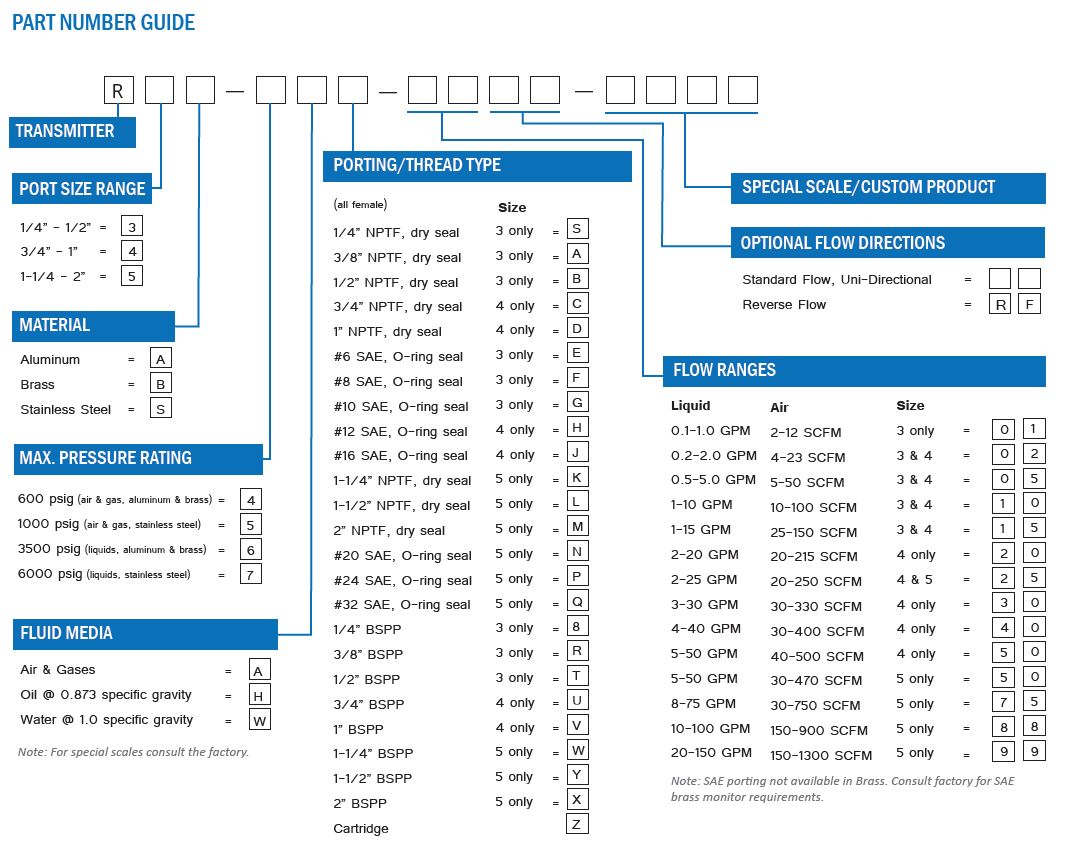

- Part Number Guide

- Downloads

-

Description

Technical Specifications

- Simple to Install: All transmitters are factory calibrated and ship fully assembled. Simply install the transmitter into your system and apply power. No straight plumbing required at inlet or outlet.

- Industry Standard Outputs: Transmitters provide proportional analog or pulse outputs that will drive popular data acquisition devices, meters and analog input cards.

- Direct Reading: All transmitters provide a visual indication of flow rate that matches the transmitted output.

- Weather-Tight Construction: The rugged cast aluminum enclosure is built to NEMA 4X standard and allows installation outdoors and in environments where liquid tight seals are required.

- Rugged and Reliable: Without delicate internal components to break, abrade or corrode, the flow transmitter will provide many years of low-maintenance service

ElectronicsMeasuring Accuracy:

Liquids

±2.0% of full scale for oil and waterAir/Gas

±2.5% of full scale in center third of measuring range;

±4% in upper & lower thirds for air and gasRepeatability:

±1% of full scale

Flow Measuring Range:

0.1-150 GPM (0.5-550 LPM)

2-1300 SCFM (1-600 SLPS)

Maximum Operating Pressure:

Liquids

Aluminum & Brass: 3500 PSIG (240 Bar)

Stainless Steel: 6000 PSIG (410 Bar)Air/Gas

Aluminum and brass: 600 PSIG (40 Bar)

Stainless steel: 1000 PSIG (69 Bar)Maximum Operating Temperature:

Media: 185°F (85°C)

Ambient: 185°F (85°C)Standard Calibration Fluids:

Oil meters: DTE 25® @ 110°F (43°C), 0.873 sg

Water meters: tap water @ 70°F (21°C), 1.0 sg

Air meters: air @ 70°F (21°C), 1.0 sg and 100 PSIG (6.8 Bar)Filtration Requirements:

74 micron filter or 200 mesh screen minimum

Viscosity

Standard viscosities up to 110 cSt. For viscosities between 110 to 430 cSt contact factory.

Materials of Construction (non-wetted components):

Enclosure & Cover: Painted Aluminum

Seals: Buna-N®

Window: Pyrex®

Din Connector: Polyamide

MATERIALS OF CONSTRUCTION (WETTED COMPONENTS):

Casing & End Ports: Anodized Aluminum, Brass, or Stainless Steel

Seals:

Anodized Aluminum: Buna-N® (STD), EPR, FKM, or Kalrez®

Brass: Buna-N® (STD), EPR, FKM, or Kalrez®

Stainless Steel 303: FKM with PTFE backup (STD), Buna-N®, EPR or Kalrez®

Transfer Magnet: PTFE coated Alnico

All other internal parts: Stainless steel

Pressure Differential Graphs Part Number Guide DownloadsElectronic Transmitter Performance:

Power Requirements:

12-24 VDC

Load Driving Capacity:

4-20mA: Load resistance is dependent on power supply voltage. Use the following equation to calculate maximum load resistance: Max Loop Load (Ω) = 50 (Power supply volts – 12).

0-5 VDC: Minimum load resistance 1000.

1-5 VDC: Minimum load resistance 25 K Ω

Square Wave Pulse: Minimum load resistance 1000 Ω

Transmission Distance:

4-20mA and 1-5 VDC (regulated) are limited only by wire resistance and power supply voltage.

<200 feet recommended for 0-5 VD (regulated) C and square wave pulse.

Over-Current Protection:

Self limiting at 35mA

Resolution:

10-bit (0.1%)

Response Time:

<100 milliseconds