The Phosphate Ester Flow Meter is a Variable Area Flow Meter offering a low cost alternative for measuring heavier, solvent-based materials and lubricants. The superior weather-tight construction of this flow meter allows for use in outdoor environments and where wash-downs are required. By using a Pyrex® tube and special seals, this meter is compatible with more aggressive fluids. The standard selection of NPT, SAE, and BSPP ports reduce the number of adapters needed for an easy installation.

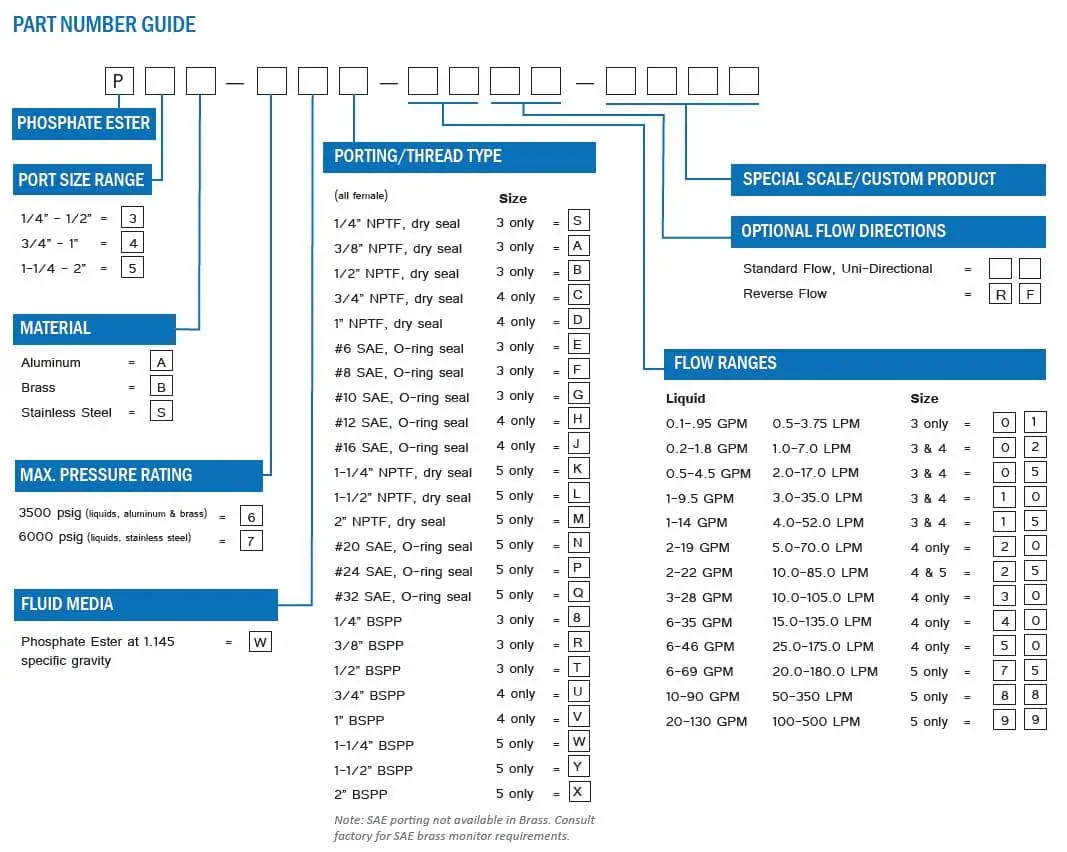

- Choice of Materials: Select from aluminum, brass or stainless steel to meet system and liquid requirements.

- Unrestricted Mounting: Allows for horizontal, vertical or inverted installation and does not require straight plumbing on inlet or outlet.

- Multi-Use: Factory calibrated for phosphate esters, these versatile meters can be used to verify hydraulic power unit outputs, as well as test machinery and tools for proper fluid flow rates.

- Rugged and Reliable: These meters are constructed with all metal pressure vessels that allow safe & permanent installation.

- High Pressure Operation: The magnetically coupled follower design allows operation to 6000 PSIG and use with liquids.

- Multiple Ports Available: Standard selection of NPT, SAE and BSPP ports reduces the amount of adapters required for installation.

±2.0% of full scale

±1% of full scale

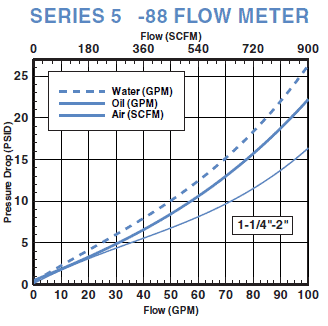

0.1-130 GPM (0.5-500 LPM)

Aluminum and brass meters: 3500 PSIG (240 Bar), Stainless steel meters: 6000 PSIG (410 Bar)

240°F (116°C)

Tap water @ 70°F (21°C) 1.0 s.g.

Meters are density corrected to 1.145 sg

74 micron filter or 200 mesh screen minimum

Window Tube: Pyrex®

Window Seals: PTFE

Casing & End Ports: Anodized Aluminum, Brass, or Stainless Steel

Seals: EPR, w/ PTFE backup, FKM or FFKM optional

Transfer Magnet: PTFE coated Alnico

All other internal parts: Stainless steel

Real-World Applications

Skydrol Monitoring in Aircraft