10-24 VDC

8 mA @ 12 VDC

12 mA @ 24 VDC

65 mA Maximum

Flow dependent, 0.5 Hz minimum

VHIGH = VSUPPLY – 0.7 Volts

VLOW = 0 Volts

50% ± 15%

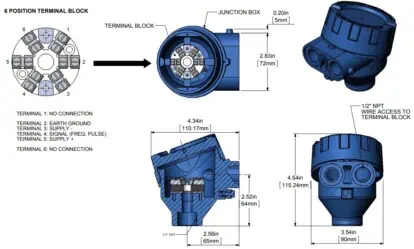

- Terminal block, 1/2” female NPT conduit entrance

- Cable with 1/2″ male NPT

- Class I, Div. I, Groups C, D

- Class II, Div. I, Groups E, F, G

- Class III

II 2 G, Ex d IIB+H2 T5 Gb, Ta = -40°C to +60°C

Ex d IIB+H2 T5 Gb Ta = -40°C to +60°C

- -4 to 140°F (-20 to 60°C )

- 185°F (85°C) maximum fluid temperature

CSA (US & Canada) or IECEx / ATEX

Square wave with a duty cycle of approximately 50%

Real-World Applications

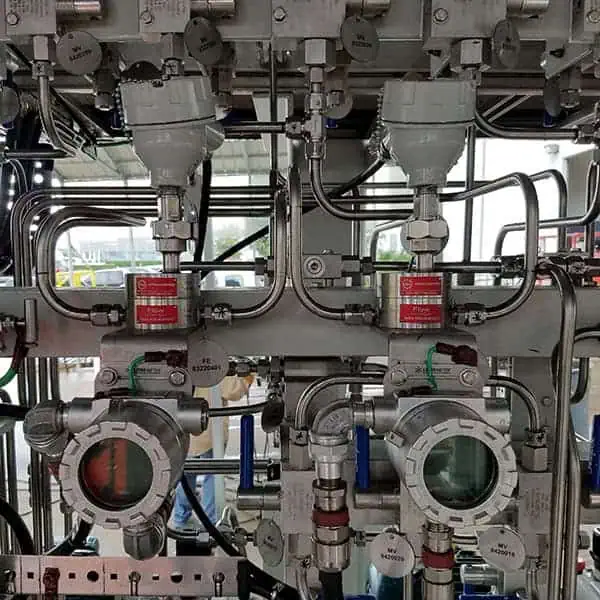

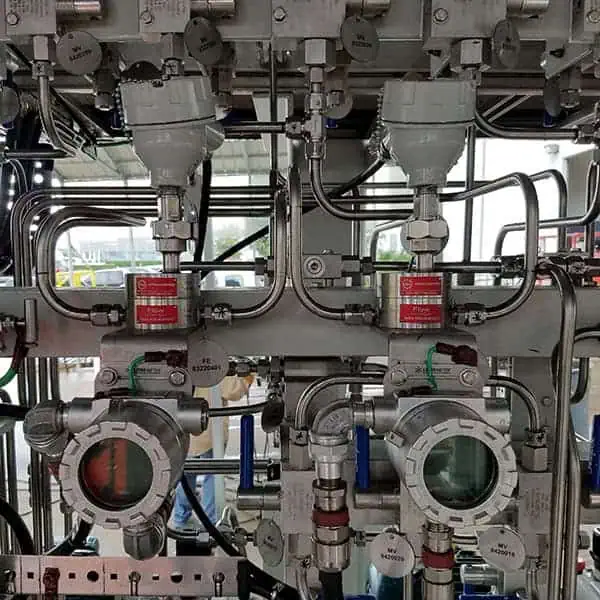

Offshore Chemical Injection

The HUB-40EX Transmitter is a great choice for offshore chemical injection skids when no local display is needed. These units are built to withstand harsh environments, including extreme temperatures, high humidity, and saltwater exposure. They are certified for hazardous areas and are made of corrosion resistant materials. Their smaller footprint are also an advantage on crowded skids.

Hydraulic Test Stands

Fracking operations require chemical injection systems to monitor and inject chemicals such as corrosion inhibitors, biocides, and H2S inhibitors into fracking fluid to ensure flow assurance and reduce well contamination. These systems, often mounted on movable trailers, must operate effectively in various environmental conditions, including extreme temperatures.

Industrial Paint Booths

In paint operations, the need for Ex certified electronics is critical due to the presence of flammable solvents and volatile organic compounds (VOCs). These substances create a hazardous environment where even a small spark could lead to an explosion or fire. The Ex-certified HUB-40EX Transmitter is specifically designed and tested to prevent ignition in such volatile conditions, ensuring the safety of the workplace and compliance with stringent industry regulations.

Offshore Chemical Injection

The HUB-40EX Transmitter is a great choice for offshore chemical injection skids when no local display is needed. These units are built to withstand harsh environments, including extreme temperatures, high humidity, and saltwater exposure. They are certified for hazardous areas and are made of corrosion resistant materials. Their smaller footprint are also an advantage on crowded skids.

Hydraulic Test Stands

Fracking operations require chemical injection systems to monitor and inject chemicals such as corrosion inhibitors, biocides, and H2S inhibitors into fracking fluid to ensure flow assurance and reduce well contamination. These systems, often mounted on movable trailers, must operate effectively in various environmental conditions, including extreme temperatures.

Industrial Paint Booths

In paint operations, the need for Ex certified electronics is critical due to the presence of flammable solvents and volatile organic compounds (VOCs). These substances create a hazardous environment where even a small spark could lead to an explosion or fire. The Ex-certified HUB-40EX Transmitter is specifically designed and tested to prevent ignition in such volatile conditions, ensuring the safety of the workplace and compliance with stringent industry regulations.