SRZ-TC Helical Flow Meter

SRZ-TC Helical PD flow meters with tungsten carbide sleeve bushing were designed for measuring high viscosity, abrasive, and filled fluids as well as lubricating and non-lubricating fluids. Temperature fluctuations and the resulting change in viscosity of the fluid only marginally affect the measuring accuracy of these helical gear flow meters. Practical applications include:

- Polyurethanes and polymers

- Adhesives and sealants

- Petrochemical products

- Light and heavy fuel oil

±0.5% over full range with 30cP fluid

± 0.05%

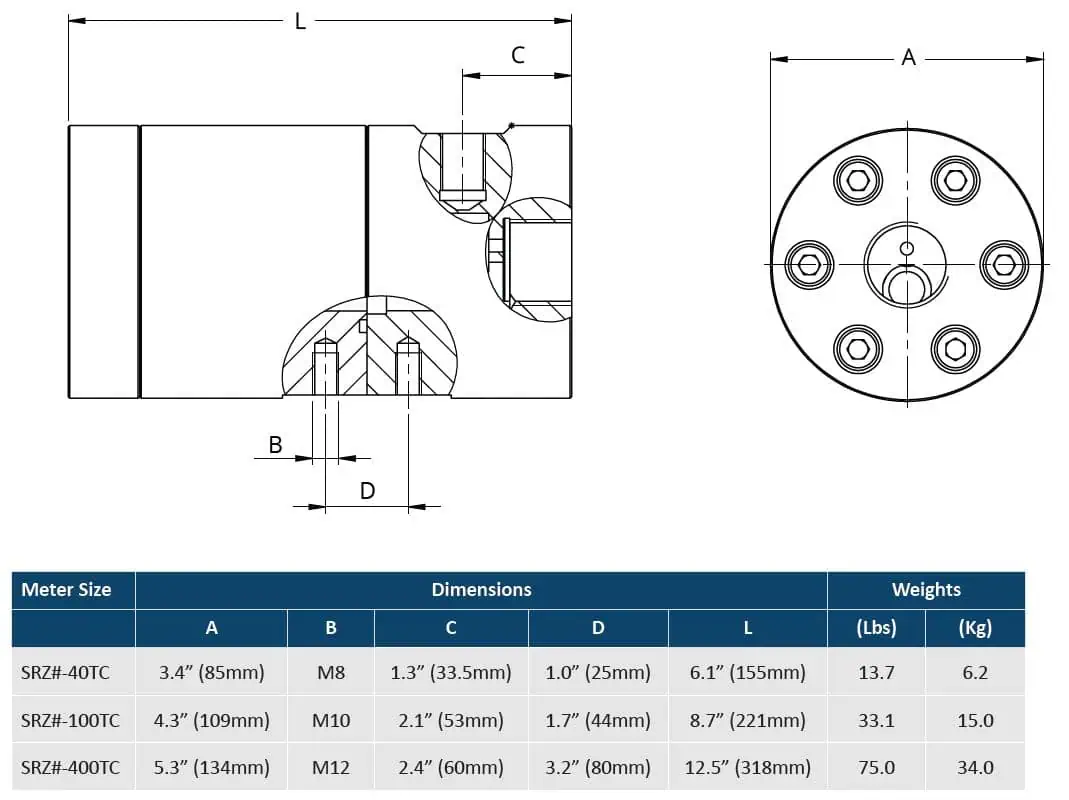

SRZx-40TC: 0.1 to 10.6 gpm | 0.4 to 40 lpm

SRZx-100TC: 0.26 to 26.4 gpm | 1.0 to 100 lpm

SRZx-400TC: 1.1 to 105.7 gpm | 4.0 to 400 lpm

4,500 psi | 315 bar

-40°F to 302°F (-40°C to 150°C)

NPT standard, BSPP optional

100:1

- Body: 303 Stainless Steel or 316L Stainless Steel

- Helical Gears: Stainless Steel (DIN 1.4122) (QPQ coating)

- Index Gear: Stainless Steel (DIN 1.4122)

- O-ring: FKM or PTFE

- Sleeve Bushing & Shafts: Tungsten Carbide

- Bolts: Zinc Flake Coated Carbon Steel

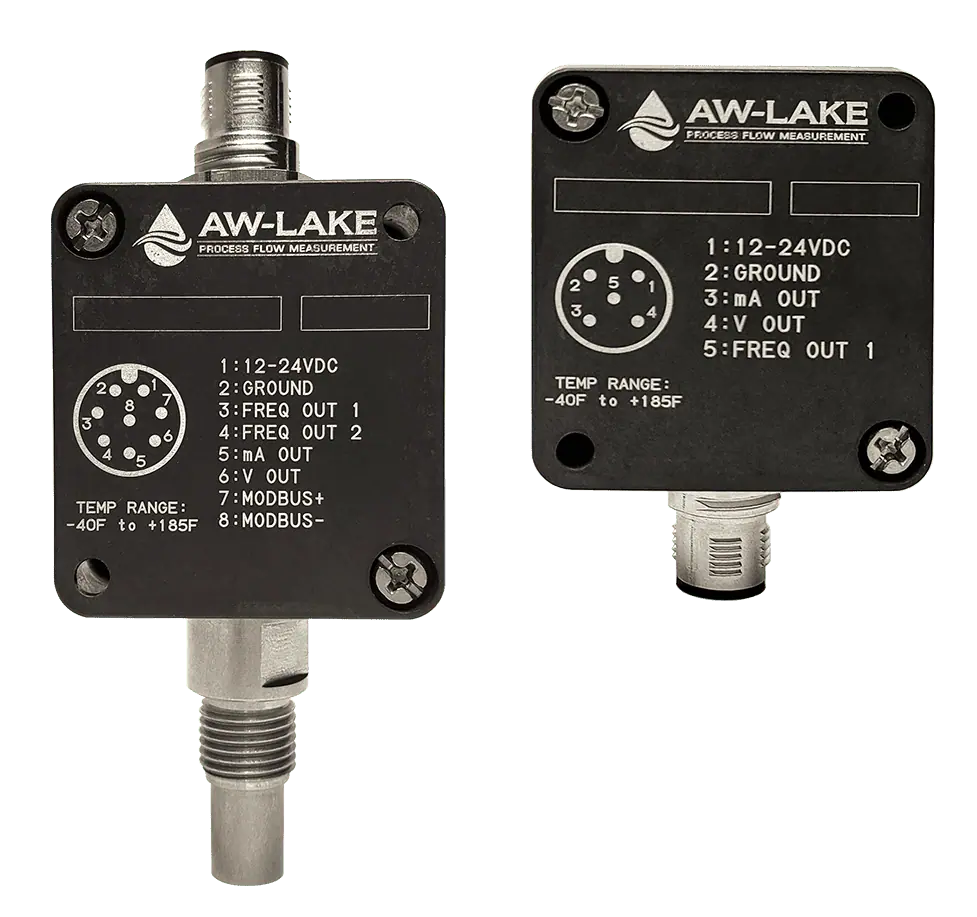

Choose from a wide variety of pickups, sensors, monitors, and controllers to pair with your gear meter:

- Frequency

- Analog (voltage or 4-20mA)

- Battery, loop, or DC powered displays

Real-World Applications

Sealant Dispensing

Because of their design, SRZ-TC Helical gear meters are often chosen for sealant dispensing applications where viscosities are high and so are the precision requirements. Such sealant materials are used in many manufacturing operations for corrosion resistance, weather protection, and general sealing of critical areas.

Automotive Under Body Coating

The SRZ-TC Helical Gear Meter is employed to measure high-viscosity PVC sealants used as an underbody coating for automotive chassis to enhance corrosion resistance. This type of flow meter is ideal for handling viscous materials because its helical gear mechanism ensures accurate measurement and consistent flow rates, even with thick substances. The PVC sealant, applied to the chassis, forms a durable protective layer, shielding the metal from moisture, chemicals, and abrasives.

Automotive Paint Operations

The SRZ Helical Flow Meter is ideal for automotive paint booths because its robust design ensures precise measurement and consistent performance, overcoming the limitations that causes other meters to fail. The SRZ-TC is able to maintain accuracy despite the challenging conditions. Additionally, its compatibility with PLC-based controls and ability to report usage data via Ethernet make it a perfect fit for efficient monitoring and compliance with EPA regulations.

Sealant Dispensing

Because of their design, SRZ-TC Helical gear meters are often chosen for sealant dispensing applications where viscosities are high and so are the precision requirements. Such sealant materials are used in many manufacturing operations for corrosion resistance, weather protection, and general sealing of critical areas.

Automotive Under Body Coating

The SRZ-TC Helical Gear Meter is employed to measure high-viscosity PVC sealants used as an underbody coating for automotive chassis to enhance corrosion resistance. This type of flow meter is ideal for handling viscous materials because its helical gear mechanism ensures accurate measurement and consistent flow rates, even with thick substances. The PVC sealant, applied to the chassis, forms a durable protective layer, shielding the metal from moisture, chemicals, and abrasives.

Automotive Paint Operations

The SRZ Helical Flow Meter is ideal for automotive paint booths because its robust design ensures precise measurement and consistent performance, overcoming the limitations that causes other meters to fail. The SRZ-TC is able to maintain accuracy despite the challenging conditions. Additionally, its compatibility with PLC-based controls and ability to report usage data via Ethernet make it a perfect fit for efficient monitoring and compliance with EPA regulations.

We work with you to increase process efficiency, reduce costly production down-time, establish real-time monitoring and control, and provide the critical tracking and record keeping necessary to meet EPA regulations.

Application Stories

High Viscosity PVC Sealants in Automotive Production Line – SRZ – Application Stories