The Flow Rate Alarm ensures sufficient flows of coolants and lubricants in mobile hydraulic equipment and industrial process control. This variable area flow meter comes equipped with simple on/off logic and a field adjustable alarm setting for simplicity of use. The rugged cast aluminum NEMA type 4X enclosure allows for weather-tight construction in outdoor environments where liquid tight seals are required. Take advantage of the economical protection with the Flow Rate Alarm. It sends alerts of incorrect pneumatic, lubrication or cooling volumes, which protects expensive equipment and reduces production downtime.

Field Adjustable Alarm Setting: Only an allen wrench is required to change the flow alarm setting.

Weather-Tight Construction: Rugged cast aluminum NEMA type 4X enclosure allows installation outdoors and in environments where liquid tight seals are required.

Simple On/Off Logic Positive: alarm points using dry-contact, SPDT switches, reduce the complexity found in standard rotameter OFF/ON/OFF circuits.

Pre-Wired with Cable Disconnect: The standard Hirschmann interconnection provides easy installation and maintenance of the Flow Alarm and the system it is a part of.

Economical Protection: This monitor rapidly pays for itself as it “sounds the alarm” on incorrect pneumatic, lubrication or cooling volumes, protecting expensive equipment and reducing downtime.

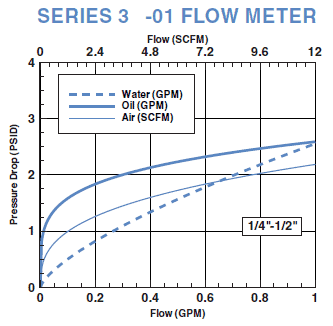

Liquids

±2.0% of full scale for oil and water;

Air/Gas

±2.5% of full scale in center third of measuring range;

±4% in upper & lower thirds for air and gas

±1% of full scale

0.1-150 GPM (0.5-550 LPM)

2.0-1300 SCFM (1-600 SLPS)

Liquids

Aluminum and brass monitors: 3500 PSIG (240 Bar)

Stainless steel: 6000 PSIG (410 Bar)

Air/Gas

Aluminum and brass: 600 PSIG (40 Bar)

Stainless steel: 1000 PSIG (69 Bar)

185°F (85°C)

Oil meters: DTE 25® @ 110°F (43°C), 0.873 sg

Water meters: tap water @ 70°F (21°C), 1.0 sg

Air meters: air @ 70°F (21°C), 1.0 sg and 100 PSIG (6.8 Bar)

4% of full scale

SPDT (dry contact). 10 amps and 1/4 hp, 125 or 250 VAC. 1/2 amp, 125 VDC (regulated); 1/4 amp, 250 VDC (regulated); 3 amps, 125 VAC “L” (lamp load)

Standard viscosities up to 110 cSt. For viscosities between 110 to 430 cSt contact factory.

74 micron filter or 200 mesh screen minimum

Enclosure & Cover: Painted Aluminum

Seals: Buna-N®

Window: Pyrex®

Din Connector: Polyamide

Casing & End Ports:

Anodized Aluminum: Buna-N® (STD), EPR, FKM or Kalrez®

Brass: Buna-N® (STD), EPR, FKM or Kalrez®

Stainless Steel: FKM with PTFE backup (STD), Buna-N®, EPR or Kalrez®

Transfer Magnet: PTFE coated Alnico

All other internal parts: Stainless steel

Real-World Applications

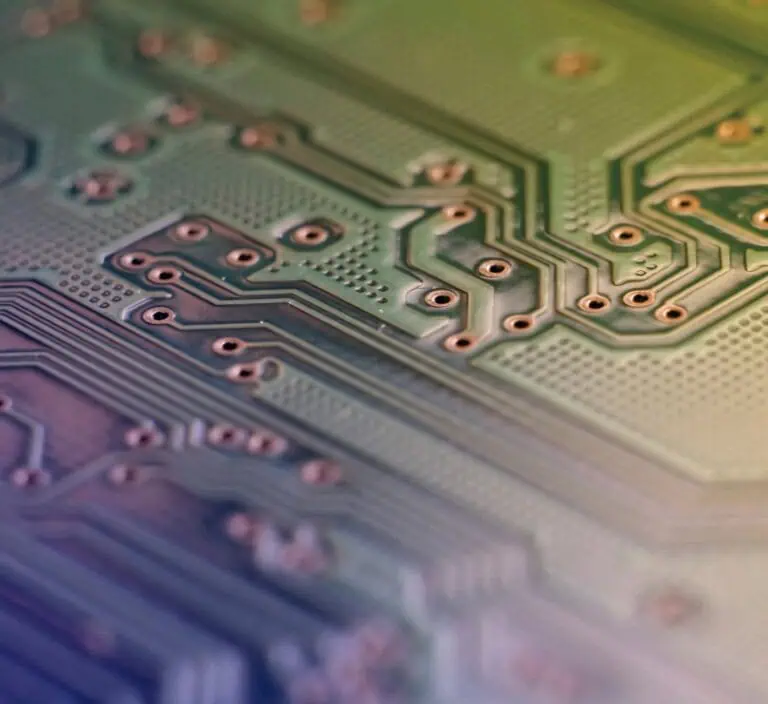

Cooling in Circuit Board Production

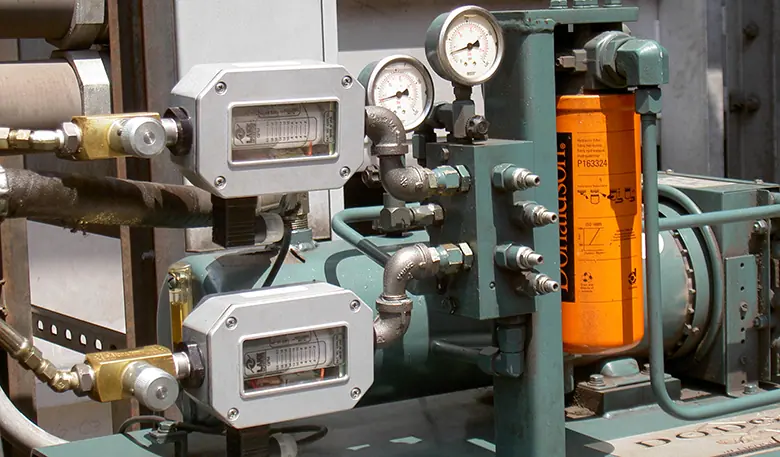

Bearing Lubrication in Mining Equipment

Stone crushers in the mining and cement industries grind rocks into smaller particles, using various types of crushers, each employing bearings to support loads and allow for misalignment. Bearing damage can occur from contamination or inadequate lubrication. AW-Lake Flow Rate Alarms are integrated into the crusher lubrication system to monitor oil flow and alert operators of minimal flow conditions, ensuring proper lubrication and preventing premature bearing wear and equipment downtime.

Steel Mills Spray Protective Layer of Oil

In steel mills, hot oil is sprayed on coil steel to prevent scaling, which is the formation of oxide layers on the steel surface at high temperatures. This protective oil barrier minimizes oxidation, preserving the steel’s quality. Flow meters monitor the hot oil flow rate, ensuring the correct amount is uniformly applied, optimizing protection, and reducing waste. They provide real-time data and alerts for deviations, allowing immediate corrective actions to maintain efficient scaling prevention.

Cooling in Circuit Board Production

Bearing Lubrication in Mining Equipment

Stone crushers in the mining and cement industries grind rocks into smaller particles, using various types of crushers, each employing bearings to support loads and allow for misalignment. Bearing damage can occur from contamination or inadequate lubrication. AW-Lake Flow Rate Alarms are integrated into the crusher lubrication system to monitor oil flow and alert operators of minimal flow conditions, ensuring proper lubrication and preventing premature bearing wear and equipment downtime.

Steel Mills Spray Protective Layer of Oil

In steel mills, hot oil is sprayed on coil steel to prevent scaling, which is the formation of oxide layers on the steel surface at high temperatures. This protective oil barrier minimizes oxidation, preserving the steel’s quality. Flow meters monitor the hot oil flow rate, ensuring the correct amount is uniformly applied, optimizing protection, and reducing waste. They provide real-time data and alerts for deviations, allowing immediate corrective actions to maintain efficient scaling prevention.