The Flow Rate Transmitter is ideal for batching, industrial process control, mobile hydraulic equipment and computer / PLC controlled hydraulic system monitoring applications. It is designed without delicate internal components to break, abrade, or corrode. The weather tight construction includes a rugged cast aluminum enclosure built to NEMA 4X standard for installation outdoors. This variable area flow meter is used to measure air, gas, oil, and water. The transmitter provides a visual indication of flow rate that matches the transmitted output for direct reading.

- Simple to Install: All transmitters are factory calibrated and ship fully assembled. Simply install the transmitter into your system and apply power. No straight plumbing required at inlet or outlet.

- Industry Standard Outputs: Transmitters provide proportional analog or pulse outputs that will drive popular data acquisition devices, meters and analog input cards.

- Direct Reading: All transmitters provide a visual indication of flow rate that matches the transmitted output.

- Weather-Tight Construction: The rugged cast aluminum enclosure is built to NEMA 4X standard and allows installation outdoors and in environments where liquid tight seals are required.

- Rugged and Reliable: Without delicate internal components to break, abrade or corrode, the flow transmitter will provide many years of low-maintenance service

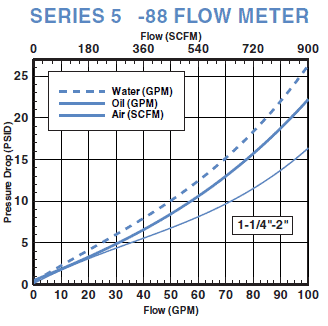

Liquids

±2.0% of full scale for oil and water

Air/Gas

±2.5% of full scale in center third of measuring range;

±4% in upper & lower thirds for air and gas

±1% of full scale

0.1-150 GPM (0.5-550 LPM)

2-1300 SCFM (1-600 SLPS)

Liquids

Aluminum & Brass: 3500 PSIG (240 Bar)

Stainless Steel: 6000 PSIG (410 Bar)

Air/Gas

Aluminum and brass: 600 PSIG (40 Bar)

Stainless steel: 1000 PSIG (69 Bar)

Media: 185°F (85°C)

Ambient: 185°F (85°C)

Oil meters: DTE 25® @ 110°F (43°C), 0.873 sg

Water meters: tap water @ 70°F (21°C), 1.0 sg

Air meters: air @ 70°F (21°C), 1.0 sg and 100 PSIG (6.8 Bar)

74 micron filter or 200 mesh screen minimum

Standard viscosities up to 110 cSt. For viscosities between 110 to 430 cSt contact factory.

Enclosure & Cover: Painted Aluminum

Seals: Buna-N®

Window: Pyrex®

Din Connector: Polyamide

Casing & End Ports: Anodized Aluminum, Brass, or Stainless Steel

Seals:

Anodized Aluminum: Buna-N® (STD), EPR, FKM, or Kalrez®

Brass: Buna-N® (STD), EPR, FKM, or Kalrez®

Stainless Steel 303: FKM with PTFE backup (STD), Buna-N®, EPR or Kalrez®

Transfer Magnet: PTFE coated Alnico

All other internal parts: Stainless steel

Electronic Transmitter Performance:

Power Requirements:

12-24 VDC

Load Driving Capacity:

4-20mA: Load resistance is dependent on power supply voltage. Use the following equation to calculate maximum load resistance: Max Loop Load (Ω) = 50 (Power supply volts – 12).

0-5 VDC: Minimum load resistance 1000.

1-5 VDC: Minimum load resistance 25 K Ω

Square Wave Pulse: Minimum load resistance 1000 Ω

Transmission Distance:

4-20mA and 1-5 VDC (regulated) are limited only by wire resistance and power supply voltage.

<200 feet recommended for 0-5 VD (regulated) C and square wave pulse.

Over-Current Protection:

Self limiting at 35mA

Resolution:

10-bit (0.1%)

Response Time:

<100 milliseconds

Real-World Applications

Pulp & Paper Process Water

In the pulp and paper industry, AW-Lake’s Flow Rate Transmitters are essential for monitoring process water to help maintain the quality of the paper, optimize water usage, and reduce waste. They enable accurate control over the amount of water used in various stages of production such as pulping, bleaching, and paper forming. Additionally, flow meters assist in detecting leaks or irregularities in the system, contributing to more efficient water management and compliance with environmental regulations.

Die Cast Coolants

The Flow Rate Transmitter is used to monitor the coolant flow to a die cast machine and its molds, ensuring optimal thermal management during the casting process. By providing precise real-time data on the coolant’s flow rate, the flow meter helps maintain consistent temperatures, preventing overheating and ensuring the quality and integrity of the cast parts. This accurate monitoring allows for timely adjustments to the coolant flow, enhancing the efficiency and reliability of the die casting operation while reducing the risk of defects and improving overall production performance.

Water Usage in Poultry Processing

The Flow Rate Transmitter is used to measure the hot water usage in the picking area of the poultry processing plant. By monitoring the water flow rate, operators can adjust the water valves to achieve optimal water, reducing water waste and overflow. The excess water can then be recycled and reused for other purposes, such as cleaning or cooling, after being filtered and treated. This way, the flow transmitter helps the customer conserve water and energy, lower their operational costs, and comply with environmental standards.

Pulp & Paper Process Water

In the pulp and paper industry, AW-Lake’s Flow Rate Transmitters are essential for monitoring process water to help maintain the quality of the paper, optimize water usage, and reduce waste. They enable accurate control over the amount of water used in various stages of production such as pulping, bleaching, and paper forming. Additionally, flow meters assist in detecting leaks or irregularities in the system, contributing to more efficient water management and compliance with environmental regulations.

Die Cast Coolants

The Flow Rate Transmitter is used to monitor the coolant flow to a die cast machine and its molds, ensuring optimal thermal management during the casting process. By providing precise real-time data on the coolant’s flow rate, the flow meter helps maintain consistent temperatures, preventing overheating and ensuring the quality and integrity of the cast parts. This accurate monitoring allows for timely adjustments to the coolant flow, enhancing the efficiency and reliability of the die casting operation while reducing the risk of defects and improving overall production performance.

Water Usage in Poultry Processing

The Flow Rate Transmitter is used to measure the hot water usage in the picking area of the poultry processing plant. By monitoring the water flow rate, operators can adjust the water valves to achieve optimal water, reducing water waste and overflow. The excess water can then be recycled and reused for other purposes, such as cleaning or cooling, after being filtered and treated. This way, the flow transmitter helps the customer conserve water and energy, lower their operational costs, and comply with environmental standards.