Lake’s High Temperature Flow Meters enable flow monitoring of barrel heating fluids, thermal transfer fluids such as Syltherm® coolant flows, hydraulic circuits, and sub-circuits. Select from aluminum, brass, or stainless steel design for media compatibility requirements. High temperature flow meters are available for air, water, and oil flow measurement with maximum temperature of 600°F.

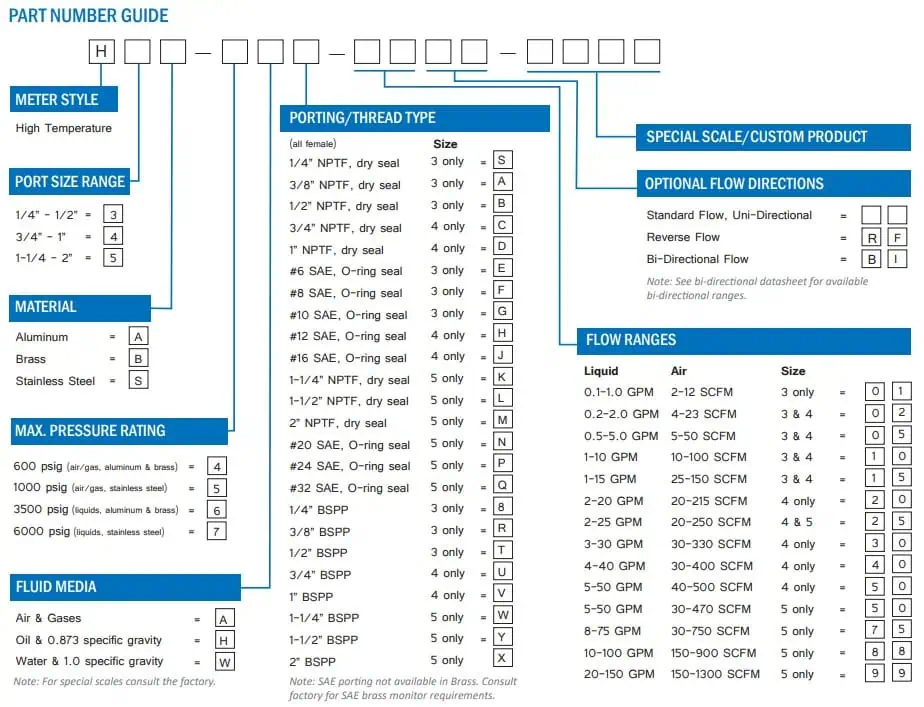

Choice of Materials: Select from aluminum, brass or stainless steel to meet system and media compatibility requirements.

Unrestricted Mounting: Allows for horizontal, vertical or inverted installation and does not require straight plumbing on inlet or outlet.

Multiple Ports Available: Standard selection of NPT, SAE and BSPP ports reduces the amount of adapters required for installation.

Bi-Directional or Reverse Flow Options: High temperature monitors are also available in bidirectional or reverse flow versions. Contact the factory for more information.

±2.0% of full scale

±1% of full scale

0.1-150 GPM (0.4-560 LPM)

Liquids

Aluminum and brass meters: 3500 PSIG (240 Bar)

Stainless steel meters: 6000 PSIG (410 Bar)

Air/Gas

Aluminum and brass meters: 600 PSIG (40 Bar)

Stainless steel meters: 1000 PSIG (69 Bar)

400°F (204°C)

Oil meters: DTE 25® @ 110°F (43°C), 0.873 sg

Water meters: water @ 70°F (21°C), 1.0 sg

Air meters: air @ 70°F (21°C), 1.0 sg & 100 PSIG (6.8 bar)

74 micron filter or 200 mesh screen minimum

Window Tube: Pyrex®

Window Seals: PTFE

Casing & End Ports: Anodized Aluminum, Brass, or Stainless Steel

Seals: FKM w/ PTFE backup

Transfer Magnet: PTFE coated Alnico

All other internal parts: Stainless steel

Real-World Applications

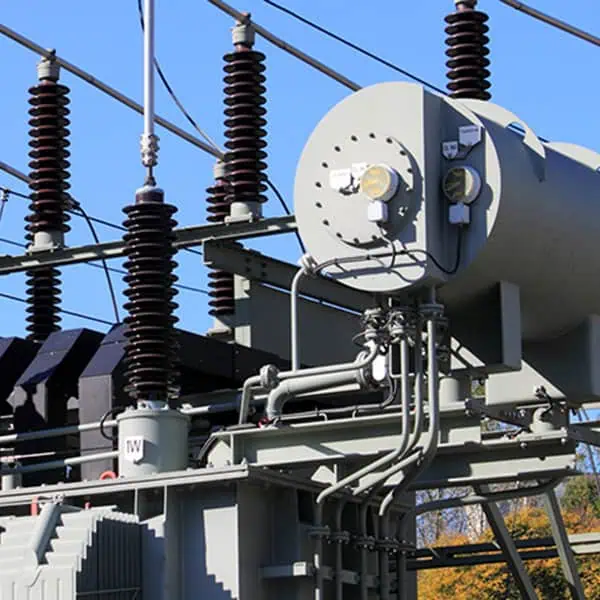

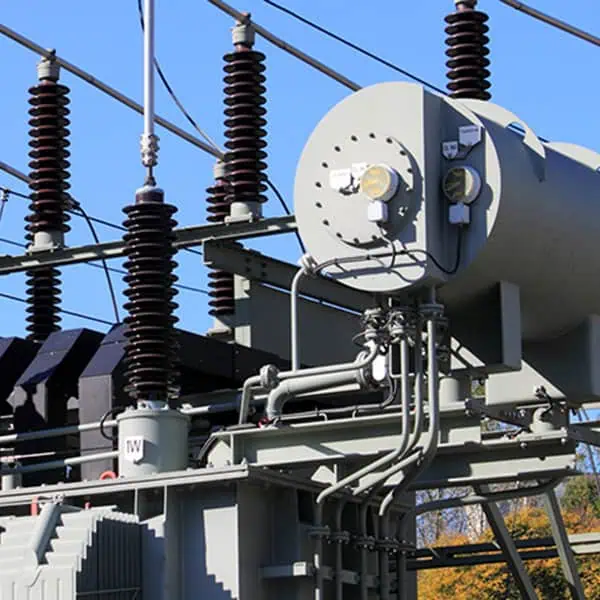

Transformer Oil Recovery

Mineral oil is circulated through a transformer to act as an insulator for components within the transformer. As the oil circulates, it dissipates the heat away from the windings to protect the coil and tapping switch from overheating. By using a flow meter to monitor the flow of this critical fluid, transformers are protected from damage caused by overheating. AW-Lake High Temperature Variable Area flow meters work well in this application.

Plastic Injection Molding

AW-Lake’s High Temperature Variable Area flow meter is used in Injection Molding operations to monitor the oil used aid in the heat transfer demands of the barrels. This is a vital part of injection molding and involves several steps, including heating the raw material and then cooling the molds after they have been filled with the molten material. If temperatures are not held at appropriate levels for specified times, defects can occur to the final product.

Transformer Oil Recovery

Mineral oil is circulated through a transformer to act as an insulator for components within the transformer. As the oil circulates, it dissipates the heat away from the windings to protect the coil and tapping switch from overheating. By using a flow meter to monitor the flow of this critical fluid, transformers are protected from damage caused by overheating. AW-Lake High Temperature Variable Area flow meters work well in this application.

Plastic Injection Molding

AW-Lake’s High Temperature Variable Area flow meter is used in Injection Molding operations to monitor the oil used aid in the heat transfer demands of the barrels. This is a vital part of injection molding and involves several steps, including heating the raw material and then cooling the molds after they have been filled with the molten material. If temperatures are not held at appropriate levels for specified times, defects can occur to the final product.