The HM-U Hydraulic System Turbine Flow Meter was designed specifically to measure hydraulic fluids like those used in the testing the performance components such as pumps, valves, and fittings. The HM-U is also a great choice for accurately measuring the flow rate of Hydraulic Power Units (HPU). This real-time data helps ensure that the hydraulic fluid flow remains within specified parameters, essential for maintaining the efficiency and reliability of the HPU. By monitoring flow rates, the HPU aids in detecting leaks, blockages, or performance issues, enabling timely maintenance and optimal operation of hydraulic machinery Due to the compact and lightweight design of the HM-U, they can be used in mobile applications. Other benefits of the HM-U include:

- Flexible 3-in-1 Instrument: Integrated connections for optional pressure and temperature measurement.

- Compact, Lightweight: Machined Aluminum (DIN 3.4365) for portable applications.

- Compatibility with Sensors: Easy to integrate with AW-Lake’s EDGE flow sensor.

- Bluetooth Connectivity: Easy setup using smart device for setting K-factor, alarms, totalization, and more.

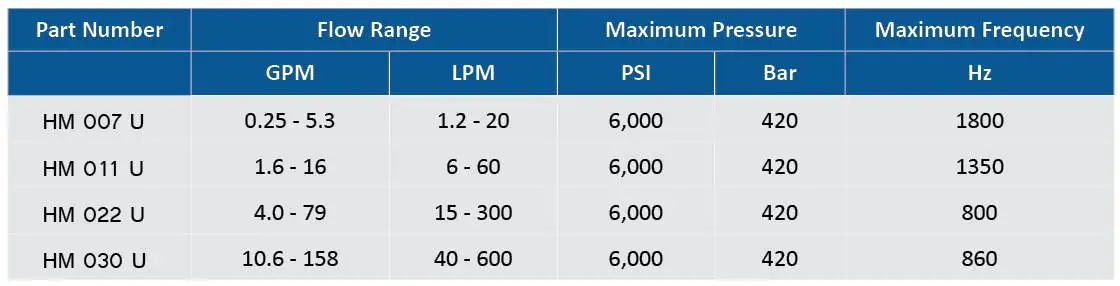

0.26 to 158.5 GPM (across all meter sizes)

±0.5% M.V. over full range with 30cP fluid

±0.5%

±2.5% of actual flow

Working pressure up to 6,000 psi (420 bar)

-40°F to 248°F | 140°C to 120°C (sensor dependent)

-40°F to 185°F | 140°C to 85°C

30cSt

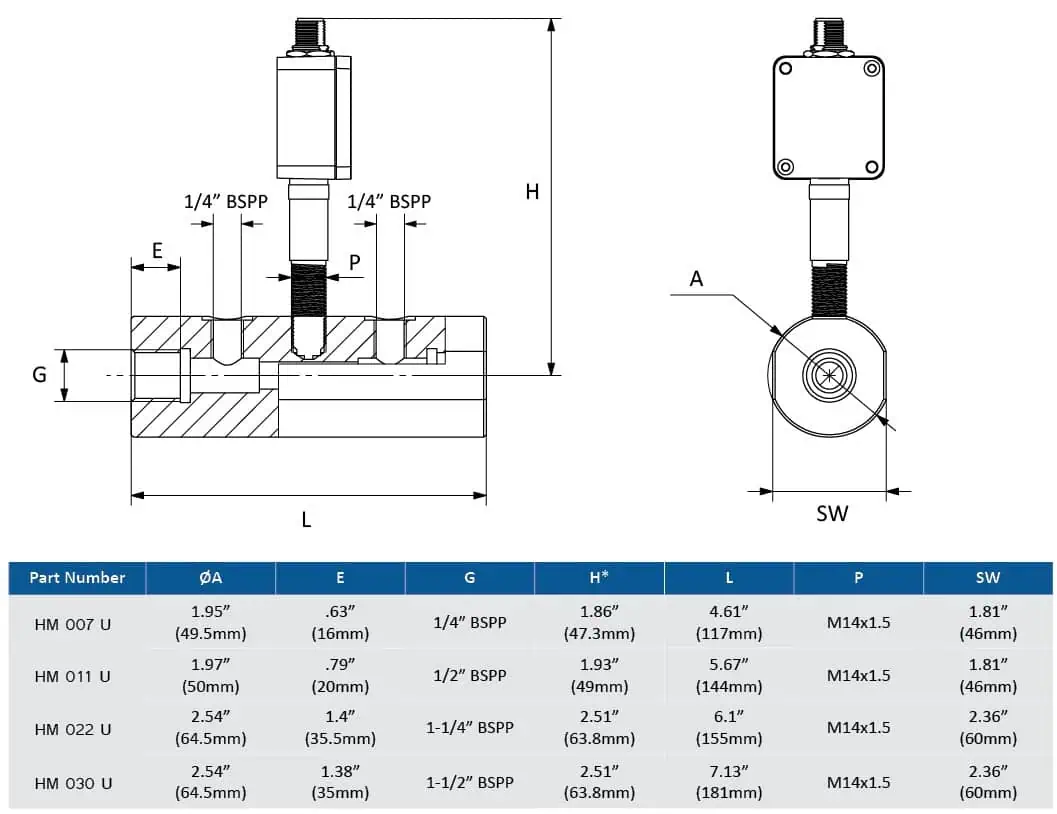

BSPP female

1/4″ BSPP ports for optional temperature and pressure sensors, (customer supplied)

up to 15:1

Body: Aluminum (DIN 3.4365)

Turbine Impeller: 420RM Stainless Steel (DIN 1.4122)

Bearings: HM 007 – 011: Tungsten carbide sleeve bearing | HM 022 – 030: Stainless steel ball bearings

Internals: 303 Stainless Steel (DIN 1.4305)

EDGE SENSOR:

Output & Part Number:

Pulse Output: EDG3-1A-17S

Analog Output: EDG3-1B-17S

Modbus Output: EDG3-1C-17S

CLICK HERE FOR MORE INFORMATION

ADDITIONAL ELECTRONICS OPTIONS:

Please contact Factory for Explosion Proof, Intrinsically Safe, High Temperature, Local or Remote Displays, or other sensor options.

Real-World Applications

Hydraulic Power Units

The HMU Hydraulic Turbine flow meter is a great choice for accurately measuring the flow rate of hydraulic fluid within a Hydraulic Power Unit (HPU). This real-time data helps ensure that the hydraulic fluid flow remains within specified parameters, essential for maintaining the efficiency and reliability of the HPU. By monitoring flow rates, the HPU aids in detecting leaks, blockages, or performance issues, enabling timely maintenance and optimal operation of hydraulic machinery

Hydraulic Test Stands

The HMU turbine meter is ideal for hydraulic test stands due to its high accuracy and repeatability, which ensure precise measurement of fluid flow. The lightweight machined aluminum housing can handle fluid temperatures from negative 40 degrees F to 248 degrees, typical among hydraulic test stands. The integrated additional connections allow users to directly connect to temperature and pressure sensors in this single unit.

Hydraulic Power Units

The HMU Hydraulic Turbine flow meter is a great choice for accurately measuring the flow rate of hydraulic fluid within a Hydraulic Power Unit (HPU). This real-time data helps ensure that the hydraulic fluid flow remains within specified parameters, essential for maintaining the efficiency and reliability of the HPU. By monitoring flow rates, the HPU aids in detecting leaks, blockages, or performance issues, enabling timely maintenance and optimal operation of hydraulic machinery

Hydraulic Test Stands

The HMU turbine meter is ideal for hydraulic test stands due to its high accuracy and repeatability, which ensure precise measurement of fluid flow. The lightweight machined aluminum housing can handle fluid temperatures from negative 40 degrees F to 248 degrees, typical among hydraulic test stands. The integrated additional connections allow users to directly connect to temperature and pressure sensors in this single unit.