JV-UF Low Viscosity Gear Meter

Built for Accurate, Repeatable Flow Measurement of Low Viscosity Fluids

The JV-UF Positive Displacement Flow Meter is part of AW-Lake’s “Next-Generation” line of Gear Meters and is the result of decades of experience, listening to customers and extensive and diligent study of the latest technologies available. This meter maintains high accuracy and repeatability, despite changing viscosity conditions, up to ±0.5% accuracy with select sensors. Applications well suited to the JV-UF meters include chemical, methanol, and fuel injection & dosing systems, test stands, hydraulic positioning systems, and coolant & lubrication monitoring.

The JV-UF positive displacement flow meters were designed specifically for low viscosity fluids, as found in the oil and gas or chemical processing sectors. The internal design of the JV-UF meter delivers greater precision than other meters and an expanded list of low viscosity fluids it can handle.

- Eliminate Waste – Maintain repeatable and accurate flow measurement, independent of changing fluid conditions. Track and report usage to quantify product/process quality, pump performance, or material levels.

- Reduce Costs – By using the correct amount of expensive/costly fluids in your process and not overdosing, you can reduce material costs. And with proper lubrication or chemical dosing you can reduce maintenance costs.

- Improve Product Quality – With flow meters that can ensure ±0.1% repeatability, you are able to maintain consistency in your processes by assuring each batch is the same. Despite long and continuous operation, these meters perform at the same level month after month… year after year.

- Operate with Ease – Paired with our smart EDGE family of flow sensors there is one easy to learn set-up procedure available via phone or PC app. Our friendly & knowledgeable staff of Application Engineers are here to help you select the right meter and get you up and running quickly.

- Enjoy Flexibility – The new meters were designed to seamlessly integrate with the EDGE sensors, which are available in panel mount, local mount, and battery, loop, or DC powered displays. Choose your output as well: Frequency or Analog (voltage or 4-20mA), or Modbus.

± 1.5% over full range (viscosity ≥ 5cP), ± 0.5% optional with select sensors:

± 2.5% over full range (viscosity ≥ 5cP) for the JV-01UF

± 0.05%

JVx-01UF: 0.0005 to 0.25 gpm | 0.72 to 360 gpd | 0.002 to 1.0 lpm

JVx-12UF: 0.005 to 0.8 gpm | 7.2 to 1152 gpd | 0.02 to 3.0 lpm

JVx-20UF: 0.02 to 2.0 gpm | 29 to 2880 gpd | 0.1 to 7.0 lpm

JVx-30UF: 0.1 to 7.0 gpm | 144 to 10,080 gpd | 0.5 to 25 lpm

JVx-60UF: 0.1 to 20 gpm | 144 to 28,800 gpd | 0.5 to 75 lpm

up to 6,000 psi

Depends on sensor used, refer to sensor page

NPT standard; BSPP optional

Body: JVM = 303 Stainless Steel, JVS – 316L Stainless Steel

Gears & Bearings: Stainless Steel (DIN 1.4122)

O-Ring: FKM, FFKM, or PTFE

Shaft: 420 Stainless Steel

Bolts: Zinc Flake Coated Carbon Steel (Inconel 718 optional)

4-point calibration

Wide variety of options: see “Choose Your Sensor” tab below for details

AW-Lake offers a wide variety of electronics options to pair with your flow meter, including Frequency, Analog, Modbus, HART, EX-rated, High Temp, Wireless, Bluetooth, Fiber Optic, and more. If you’re not sure what you need, reach out and we can help you!

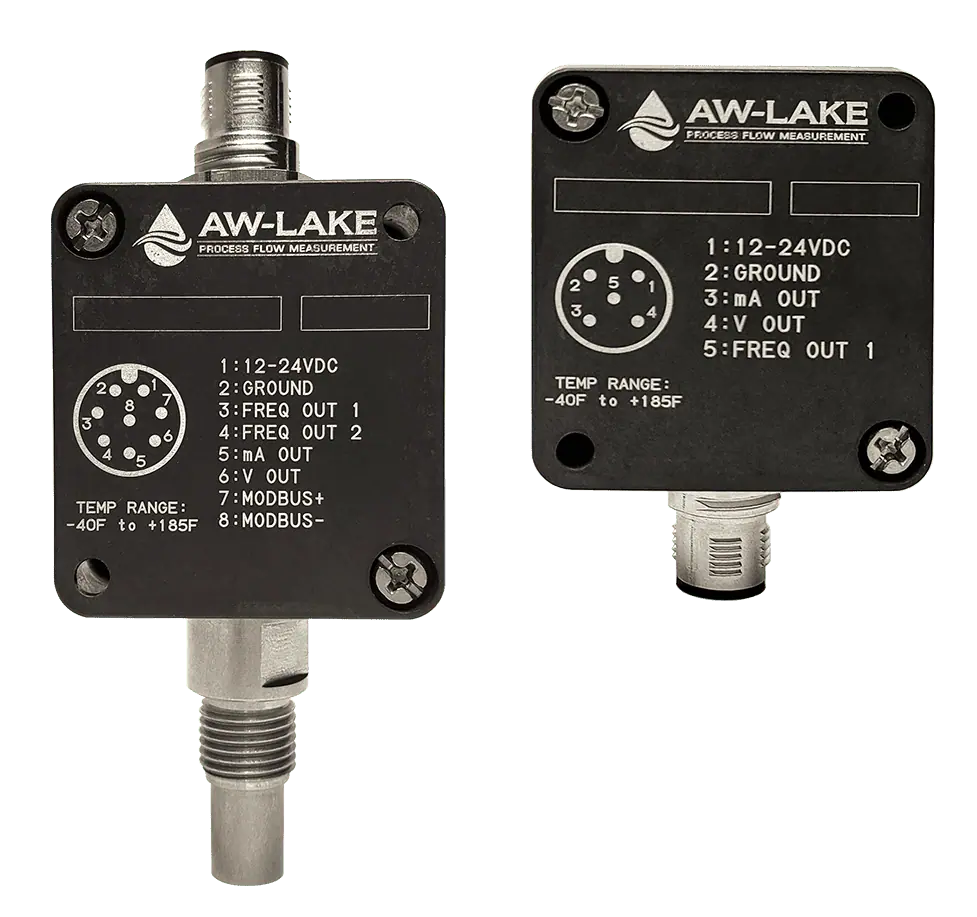

EDGE Family of Electronics:

When paired with the EDGE Family of flow electronics, the “Next Gen” meters give you your flow data in the format you need, delivered seamlessly to your PLC, PC, remote display, or smart phone. These easy to deploy EDGE sensors and displays offer innovative signal processing, increased accuracy from linearization, and flexibility to choose the output you need (pulse, analog, or Modbus). Enterprise Flow Data Delivery with an EDGE.

- The EDGE Flow Sensor (pulse, analog, Modbus, Bluetooth)

- RT-50 Flow Transmitter (Bluetooth)

- FAC-R Frequency to Analog Converter

TRANSMITTERS & CONTROLLERS:

- RT-30SD Flow Transmitter (pulse, analog, HART)

- RT-30EX Explosion-Proof Flow Transmitter (pulse, analog, HART)

- HUB-40SD Hall Effect Sensor

- HUB-40EX Explosion-proof Hall Effect Sensor

- MX 9000 Process Monitor (analog)

Additional SENSORS:

- MAG-Px Hall Effect Sensor

- MAG-J-Px Hall Effect Sensor

- FOP-20 Fiber Optic Sensor

- CAPM-2 Carrier Frequency Pickup Module

- CAPM-15 High Temp Pickup System

- VTE-02 Carrier Frequency Sensor

Real-World Applications

Offshore Chemical Injection Skids

The JV-UF gear meter is well suited to offshore chemical injection rigs requiring low flow of very low viscosity chemicals and additives. The robust construction and resilient materials of construction lend this meter perfectly to this application. With high accuracy and tolerance of pulsing flows, this meter out-performs the competition in some of the harshest environments in the world.

Dosing Packages

The JV-UF gear meter is ideal for dosing systems typically found in…..

Natural gas, LPG, and other gaseous fuels are originally odorless but highly combustible making them dangerous to distribute. To help detect any leak, a chemical odorant is added to the fuel as it leaves storage terminals. The JV-UF Series Gear Flow Meters were designed with extremely tight clearance around gears to prevent slippage; specifically, to handle low viscosity fluids like the Ethyl Mercaptan.

Offshore Chemical Injection Skids

The JV-UF gear meter is well suited to offshore chemical injection rigs requiring low flow of very low viscosity chemicals and additives. The robust construction and resilient materials of construction lend this meter perfectly to this application. With high accuracy and tolerance of pulsing flows, this meter out-performs the competition in some of the harshest environments in the world.

Dosing Packages

The JV-UF gear meter is ideal for dosing systems typically found in…..

Natural gas, LPG, and other gaseous fuels are originally odorless but highly combustible making them dangerous to distribute. To help detect any leak, a chemical odorant is added to the fuel as it leaves storage terminals. The JV-UF Series Gear Flow Meters were designed with extremely tight clearance around gears to prevent slippage; specifically, to handle low viscosity fluids like the Ethyl Mercaptan.