Pneumatic Flow Meters are ideal for monitoring air compressor outputs, pneumatic tool air consumption, and industrial gas flows. The rugged and reliable design includes all metal pressure vessels, allowing safe installation in industrial systems and industries. Enjoy the unrestricted mounting capabilities and easy installation with multiple ports available.

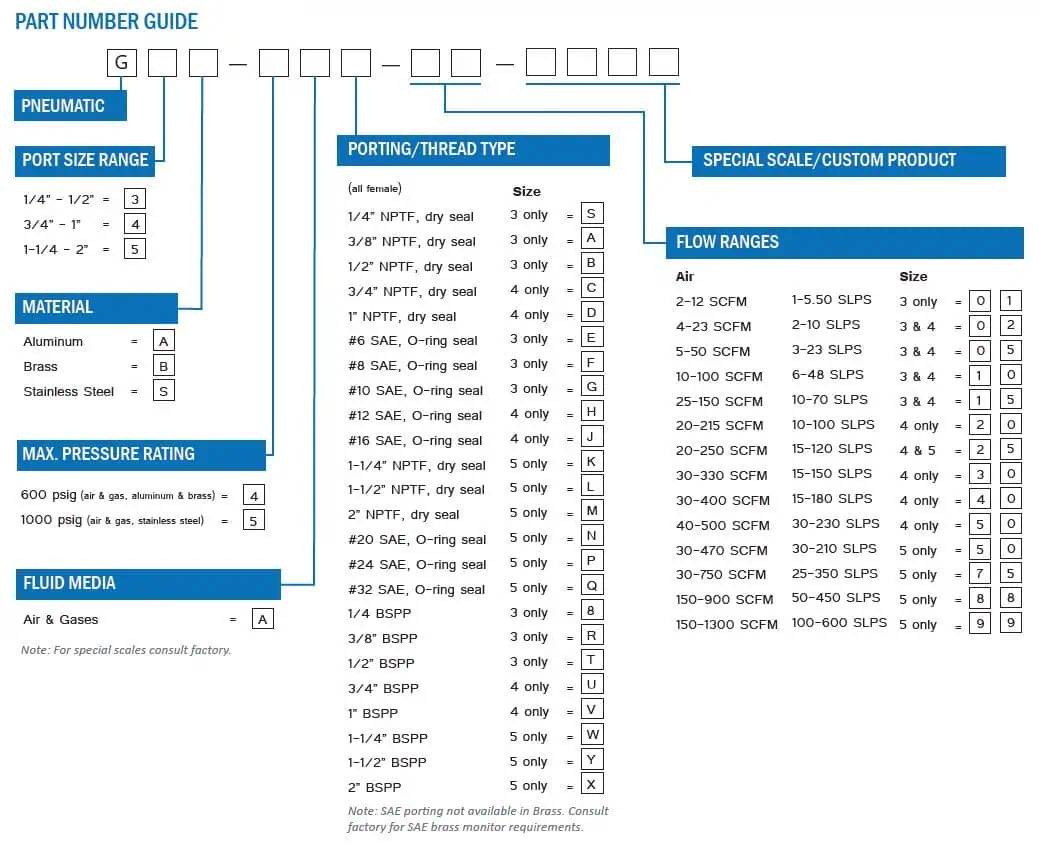

- Choice of Materials: Select from aluminum, brass or stainless steel to meet system and media compatibility requirements.

- Unrestricted Mounting: Allows for horizontal, vertical or inverted installation. Superior Exterior Design Weather-tight for use outdoors and/or on systems where wash downs are required.

- Rugged and Reliable: These monitors are constructed with all metal pressure vessels, allowing safe, permanent installation in industrial systems.

- Multiple Ports Available: Standard selection of NPT, SAE and BSPP ports reduces the amount of adapters required for installation.

±2.5% of full scale in the center third of the measuring range; ±4% in upper and lower thirds

±1% of full scale

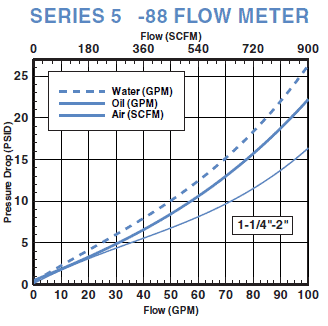

2-1300 SCFM @ 100 PSIG (1-600 LPS)

Aluminum & Brass: 600 PSIG (40 Bar)

Stainless Steel: 1000 PSIG (69 Bar)

240°F (116°C) Note: For operation to 600°F (316°C), see our High Temp datasheet.

Air @ 70°F (21°C), 1.0 sg and 100 PSIG (6.8 Bar)

74 micron filter or 200 mesh screen minimum

Window Tube: Polycarbonate

Window Seals: Buna-N®

Casing & End Ports: Anodized Aluminum, Brass, or Stainless Steel

Seals:

- Aluminum: Buna-N® (STD),EPR, FKM, or FFKM

- Brass: Buna-N® (STD),EPR, FKM, or FFKM

- Stainless Steel: FKM with PTFE backup (STD), Buna-N®, EPR or FFKM

Transfer Magnet: PTFE coated Alnico

All other internal parts: Stainless steel

Real-World Applications

Air Compressor Flow Rates

Air compressors are widely used across various industries for their safe, energy-efficient and non-heat producing operation. Measuring the air flow to air compressors is important to ensure optimal performance, energy efficiency, and system reliability. Pneumatic flow meters provide accurate air flow measurement that helps in identifying inefficiencies, detecting leaks, and maintaining proper pressure levels, which can reduce operational costs and prevent equipment failures.

Air Consumption in Blow Molding

Pneumatic flow meters are used in blow molding to monitor and control air consumption during the molding process. They measure the flow rate of compressed air supplied to the molds, ensuring that the correct amount of air is delivered for each production cycle. By providing real-time data on air usage, these flow meters help optimize the process, improve energy efficiency, and reduce costs. They also enable early detection of leaks or inefficiencies in the system, allowing for timely maintenance and minimizing downtime. This ensures consistent product quality and enhances overall production efficiency in blow molding operations.

Air Sparging Environmental Treatment

Air Compressor Flow Rates

Air compressors are widely used across various industries for their safe, energy-efficient and non-heat producing operation. Measuring the air flow to air compressors is important to ensure optimal performance, energy efficiency, and system reliability. Pneumatic flow meters provide accurate air flow measurement that helps in identifying inefficiencies, detecting leaks, and maintaining proper pressure levels, which can reduce operational costs and prevent equipment failures.

Air Consumption in Blow Molding

Pneumatic flow meters are used in blow molding to monitor and control air consumption during the molding process. They measure the flow rate of compressed air supplied to the molds, ensuring that the correct amount of air is delivered for each production cycle. By providing real-time data on air usage, these flow meters help optimize the process, improve energy efficiency, and reduce costs. They also enable early detection of leaks or inefficiencies in the system, allowing for timely maintenance and minimizing downtime. This ensures consistent product quality and enhances overall production efficiency in blow molding operations.