-40°F to 140°F (-40°C to 60°C)

3 x D Lithium battery pack. Field replaceable. Class I Div 1 certified when used with SignalFire system.

1-10 years, depending on sensor type and reporting frequency

Passive inductive flow sensor.

User-configurable (5 sec – 1 hr)

40 mW

Up to 1/2 mile

Internal weather resistant, omnidirectional

902-928 MHz, FHSS, license-free

ISM band compliant with FCC Part 15

Up to 64 separate networks

- Details of Class I, Div 1,

- Temp Code T3, Groups C&D

- Conforms to UL Std. 913

- Certified to Can/CSA Std. C22.2 No 157

Battery voltage, signal strength, error conditions

0% to 100% condensing

- Model: JV#-20TC | Flow Range: 0.03 to 2.0 GPM

- Model: JV#-30TC | Flow Range: 0.1 to 7.0 GPM

- Model: JV#-60TC | Flow Range: 0.1 to 20.0 GPM

- Model: JV#-20BB | Flow Range: 0.03 to 2.0 GPM

- Model: JV#-30BB | Flow Range: 0.1 to 7.0 GPM

- Model: JV#-60BB | Flow Range: 0.1 to 20.0 GPM

- Model: JV#-80BB | Flow Range: 0.5 to 60.0 GPM

- Model: JV#-90BB | Flow Range: 1.0 to 120.0 GPM

- Model: TRG-11.250-5 | Flow Range: 0.08 to 0.4 GPM

- Model: TRG-11.300-5 | Flow Range: 0.13 to 1.06 GPM

- Model: TRG-11.375-5 | Flow Range: 0.3 to 2.5 GPM

- Model: TRG-11.500-5 | Flow Range: 0.9 to 8.0 GPM

- Model: TRG-11.750(-5) | Flow Range: 1.6 to 11.5 GPM

- Model: TRG-11.880 | Flow Range: 3.2 to 32.0 GPM

- Model: TRG-1110 | Flow Range: 5.3 to 53.0 GPM

- Model: TRG-1120L | Flow Range: 13.0 to 200.0 GPM

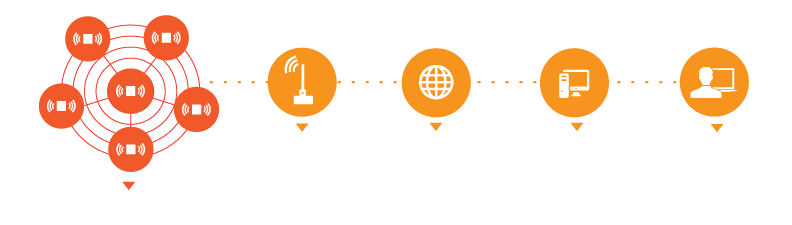

The SignalFire Remote Sensing System consists of nodes attached to sensors like the SFS-WP Wireless Flow Transmitter that work in a mesh network pattern to send data via Modbus to a Gateway, where it is transferred to a PC, PLC, or other control system.

COMPONENTS NEEDED IN SIGNALFIRE REMOTE SENSING SYSTEM:

- SFS-WP Intrinsically Safe Wireless Flow Transmitter

- JV-KG, JV-CG, or TRG Flow Meter

- Gateway Stick or Gateway DIN Mount

- SignalFire Toolkit Software (free download)

- USB Serial DB9 Configuration Cable

- USB 4-pin Node Configuration Cable

Gateway Interfaces Include:

- HART®

- 4-20mA current loop, 1-5 Volt

- Digital input (state, counter, totals, frequency)

- RS-485/Modbus

For more information on the SignalFire Remote Sensing System, visit the SignalFire website HERE.

Costs less than running 60 feet of wire & conduit.

Wireless data transmission anywhere in the world with an Internet connection.

Easy thread-in installation. A quick setup procedure allows you to have the unit working with just a few simple programming steps.

ISM bands sustain signal strength through terrain, structures or weather for a range of up to 1/2 mile.

Real-World Applications

The JV-BB and its predecessor JV-KG have been installed on hundreds of chemical injection skids throughout the Gulf of Mexico and beyond for decades. The robust construction and resilient materials of construction lend this meter perfectly to this application. With high accuracy and tolerance of pulsing flows, this meter out-performs the competition in some of the harshest environments in the world.

Hydraulic Test Stands

The JV-BB gear meter is ideal for hydraulic test stands due to its high accuracy and repeatability, which ensure precise measurement of fluid flow under varying conditions. Its robust design withstands the high pressures and temperatures typical in hydraulic systems. It can handle a wide range of viscosities and flow disturbances and its compact size and lack of need for straight run installation make it versatile and easy to integrate into complex hydraulic setups.

Onshore Chemical Injection Systems

Although onshore chemical injection systems are installed on land, at ground level, and in more stable conditions, they are still exposed to weather, varying temperatures, dust, and potential exposure to industrial pollutants. The JV-BB gear meter is still the best choice for its high accuracy and repeatability for consistently precise dosing of the valuable chemicals. Additionally, they handle a wide range of viscosities and flow rates.

Marine Fuel Monitoring

The JV-BB gear meter is ideal for marine fuel monitoring due to its robust construction, ensuring durability in harsh environments. Its repeatable accuracy ensures consistent measurements, crucial for fuel management. Unlike many meters, it doesn’t require a straight run for installation, offering flexibility in the often confined spaces of marine vessels. Additionally, its ability to detect flow in both directions ensures reliable monitoring, making it perfect for comprehensive marine fuel management systems.

The JV-BB and its predecessor JV-KG have been installed on hundreds of chemical injection skids throughout the Gulf of Mexico and beyond for decades. The robust construction and resilient materials of construction lend this meter perfectly to this application. With high accuracy and tolerance of pulsing flows, this meter out-performs the competition in some of the harshest environments in the world.

Hydraulic Test Stands

The JV-BB gear meter is ideal for hydraulic test stands due to its high accuracy and repeatability, which ensure precise measurement of fluid flow under varying conditions. Its robust design withstands the high pressures and temperatures typical in hydraulic systems. It can handle a wide range of viscosities and flow disturbances and its compact size and lack of need for straight run installation make it versatile and easy to integrate into complex hydraulic setups.

Onshore Chemical Injection Systems

Although onshore chemical injection systems are installed on land, at ground level, and in more stable conditions, they are still exposed to weather, varying temperatures, dust, and potential exposure to industrial pollutants. The JV-BB gear meter is still the best choice for its high accuracy and repeatability for consistently precise dosing of the valuable chemicals. Additionally, they handle a wide range of viscosities and flow rates.

Marine Fuel Monitoring

The JV-BB gear meter is ideal for marine fuel monitoring due to its robust construction, ensuring durability in harsh environments. Its repeatable accuracy ensures consistent measurements, crucial for fuel management. Unlike many meters, it doesn’t require a straight run for installation, offering flexibility in the often confined spaces of marine vessels. Additionally, its ability to detect flow in both directions ensures reliable monitoring, making it perfect for comprehensive marine fuel management systems.

We work with you to increase process efficiency, reduce costly production down-time, establish real-time monitoring and control, and provide the critical tracking and record keeping necessary to meet EPA regulations.

Practical Experience

- Chemical Injection

- Water Separation

- Subsea Operations

- Oil Field Management

- Hydraulic Fracturing (Fracking)

- Hydraulic System Monitoring

- Valve Actuation / Blowout Prevention

- Fuel Measurement

- Custody Transfer