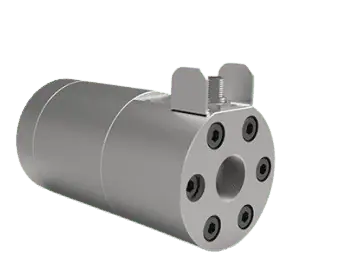

The SRZ-H High Resolution Helical PD Flow Meters are ideal for high viscosity non-lubricating and abrasive fluids with suspended particulates, such as water-based paints, polymers, glues, and sealing materials, as well as heavy fuel oils. These positive displacement flow meters are equipped with a built-in sensor and are capable of maintaining consistent accuracy of ±0.5% despite changing viscosity conditions.

Practical applications include:

- Small volume dosing applications

- Sealant and adhesive dispensing applications

- Paint reclaim and environmental tracking

- Paint circulation and supply

±0.5% over full range with 100cP fluid

± 0.05%

0.1 to 10.6 gpm*

up to 6,000 psi | 414 bar

40 to 158°F | -40 to 70°C

3/4” NPT (BSPP optional)

- Body: 303 Stainless Steel

- Helical Gears: Stainless Steel (DIN 1.4122) (QPQ1 coating)

- Index Gear: Stainless Steel (DIN 1.4122)

- O-ring: FKM or PTFE

- Sleeve Bushing & Shafts: Tungsten Carbide

- Bolts: Zinc Flake Coated Carbon Steel

STAT – High Resolution, HR – Ultra High Resolution

Electrical Specifications:

12 up to 30 VDC

Active push pull, square wave signal out max. 20 mA Duty cycle 50% nominal

Sensor N:

1 = +Supply (12 up to 30 VDC)

2 = Output signal A

3 = 0V/Ground

4 = Output signal B

5 = n.c.

– All output signals are available simultaneously

– Signals 2 and 4 are 90° phase-shifted.

Sensor R:

1 = +Supply (12 up to 30 VDC)

2 = Direction

3 = 0V/Ground

4 = Frequency output

5 = n.c.

Ingress Protection: IP67 when used with IP67 rated mating connector

Real-World Applications

2K Silicon Sealant Dispensing

The SRZ-H high resolution helical flow meter is vital for dispensing sealant and 2K silicon sealer in automotive assemblies, accurately measuring high-viscosity materials to ensure precise control. By precisely monitoring flow rates, it allows the manufacturer to apply exact amounts, such as a 3 mm bead for seam sealing Air Bag Assemblies, ensuring product quality and consistency. Additionally, the helical flow meter minimizes pressure drop and optimizes the efficiency of the dispensing equipment.

Windmill Blade Coating

The SRZ-H High Resolution Helical Flow Meter is used for monitoring adhesive flow in windmill blade assembly due to their exceptional accuracy (0.5% resolution), crucial for maintaining bond quality. They effectively withstand high pressure drops (1,740 to 2,900 psi), essential in bonding processes. Designed for highly viscous, abrasive adhesives, they meet safety standards (CSA/UL, ISO 17025, Pressure Equipment Directive).

Electric Vehicle Battery Bonding

A Helical flow meter is employed to monitor the precise flow of bonding material used to protect electric car battery systems. It ensures precise measurement of the adhesive flow rate, crucial for applying the right amount of material to safeguard battery components effectively. The meter’s design allows it to handle the viscosity and abrasiveness of the bonding material, ensuring consistent application and optimal protection of the battery system against environmental factors and mechanical stresses.

2K Silicon Sealant Dispensing

The SRZ-H high resolution helical flow meter is vital for dispensing sealant and 2K silicon sealer in automotive assemblies, accurately measuring high-viscosity materials to ensure precise control. By precisely monitoring flow rates, it allows the manufacturer to apply exact amounts, such as a 3 mm bead for seam sealing Air Bag Assemblies, ensuring product quality and consistency. Additionally, the helical flow meter minimizes pressure drop and optimizes the efficiency of the dispensing equipment.

Windmill Blade Coating

The SRZ-H High Resolution Helical Flow Meter is used for monitoring adhesive flow in windmill blade assembly due to their exceptional accuracy (0.5% resolution), crucial for maintaining bond quality. They effectively withstand high pressure drops (1,740 to 2,900 psi), essential in bonding processes. Designed for highly viscous, abrasive adhesives, they meet safety standards (CSA/UL, ISO 17025, Pressure Equipment Directive).

Electric Vehicle Battery Bonding

A Helical flow meter is employed to monitor the precise flow of bonding material used to protect electric car battery systems. It ensures precise measurement of the adhesive flow rate, crucial for applying the right amount of material to safeguard battery components effectively. The meter’s design allows it to handle the viscosity and abrasiveness of the bonding material, ensuring consistent application and optimal protection of the battery system against environmental factors and mechanical stresses.