The ClearView Value Flow Meter is used for water and hydraulic oil flow measurement. This flow meter is an economical way to monitor municipal pressure water flows, observe case drain flows, and verify pump outputs. The transparent body on this variable area flow meter allows for visual inspection of fluid conditions to diagnose any problems at a glance.

- Unrestricted Mounting: Allows for horizontal, vertical or inverted installation and does not require straight plumbing on inlet or outlet.

- Compact Design: Measures less than 8” long and 2-7/16” diameter with a rigid tube and union nut design.

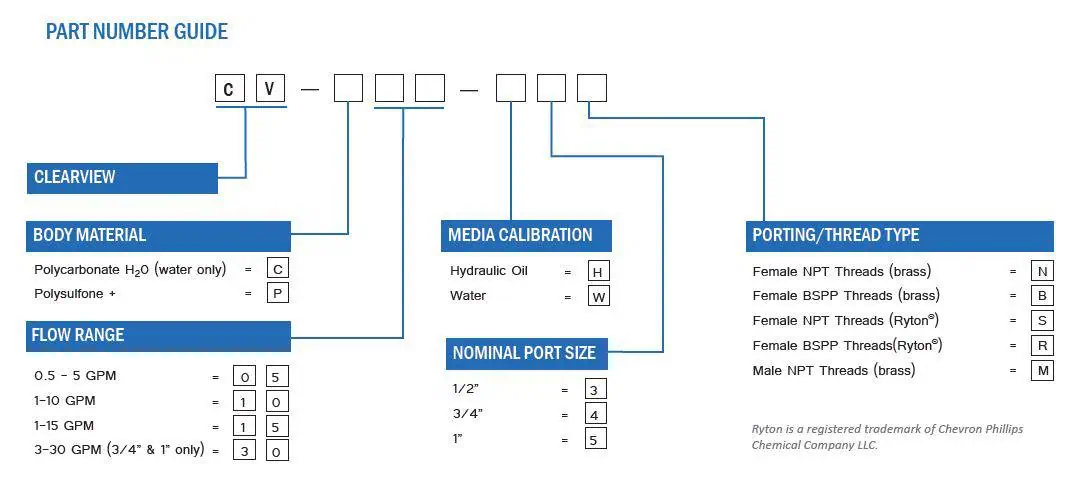

- Multiple Materials and Calibrations Available: With a variety of wetted materials of construction and media calibrations, the meter will be well suited to your process.

- Sensing Method Assures Accuracy: The proven variable area piston metering assembly provides accurate, dependable flow rate indication.

±2.0% of full scale

±1% of full scale

1-30 GPM (5-110 LPM)

325 PSIG (22.4 Bar)

ClearView H2O: 200°F (93°C) (for water)

ClearView+: 250°F (121°C)

Oil meters: DTE 25® @ 110°F (43°C), 0.873 sg

Water meters: tap water @ 70°F (21°C), 1.0 sg

74 micron filter or 200 mesh screen minimum

End Ports: Brass, Ryton®

Seals: Viton

Spring: Stainless Steel

Body: ClearView H2O – Polycarbonate, Clearview+ – Polysulfone

Indicator: Polysulfone

Horizontal, Vertical, or Inverted Installation

Enter Headland Part #:

Real-World Applications

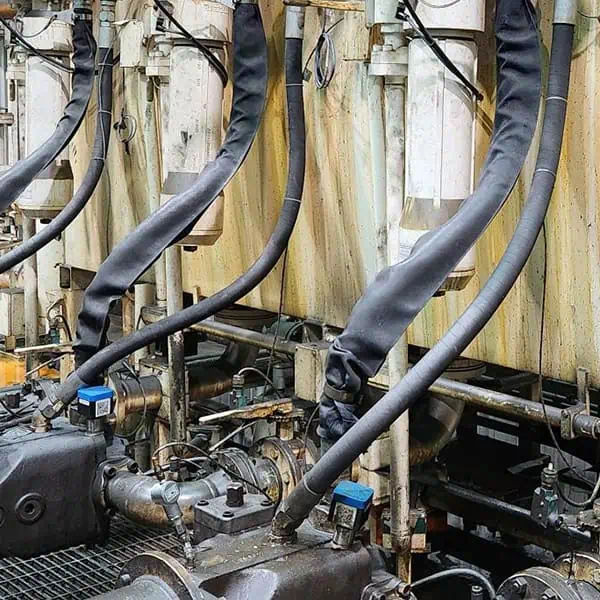

Low Cost Case Drain Monitoring

A case drain flow meter is used to measure the hydraulic fluid flowing back from the case drain of a pump or motor. This fluid is usually leakage within the pump or motor due to internal clearances. Monitoring this flow is crucial because an increase can indicate internal wear or damage, signaling potential failure. A lower-cost flow meter can effectively detect these issues early, helping to prevent major failures, reduce maintenance costs, and ensure the reliable operation of hydraulic systems.

Chemical Processing

In chemical processing, the ClearView Plus variable area flow meter is used to measure and regulate the flow rate of chemicals. Its simple, reliable design with visual indication of flow rate allows operators to easily monitor and adjust the flow to ensure precise control of chemical reactions and processes. ClearView flow meters are essential for maintaining the accuracy, efficiency, and safety of chemical processing operations.

Chiller System Water Monitoring

Using a flow meter to monitor the flow rate of water in an industrial chiller system is crucial for maintaining optimal performance and efficiency. The ClearView flow meter ensures that the correct amount of water circulates through the system, which is vital for effective heat exchange and cooling. Consistent monitoring with a flow meter aids in detecting any irregularities, such as blockages or leaks, that could impair the system’s functionality, reducing energy consumption, and extending the lifespan of the chiller, ultimately leading to cost savings and enhanced operational reliability.

Low Cost Case Drain Monitoring

A case drain flow meter is used to measure the hydraulic fluid flowing back from the case drain of a pump or motor. This fluid is usually leakage within the pump or motor due to internal clearances. Monitoring this flow is crucial because an increase can indicate internal wear or damage, signaling potential failure. A lower-cost flow meter can effectively detect these issues early, helping to prevent major failures, reduce maintenance costs, and ensure the reliable operation of hydraulic systems.

Chemical Processing

In chemical processing, the ClearView Plus variable area flow meter is used to measure and regulate the flow rate of chemicals. Its simple, reliable design with visual indication of flow rate allows operators to easily monitor and adjust the flow to ensure precise control of chemical reactions and processes. ClearView flow meters are essential for maintaining the accuracy, efficiency, and safety of chemical processing operations.

Chiller System Water Monitoring

Using a flow meter to monitor the flow rate of water in an industrial chiller system is crucial for maintaining optimal performance and efficiency. The ClearView flow meter ensures that the correct amount of water circulates through the system, which is vital for effective heat exchange and cooling. Consistent monitoring with a flow meter aids in detecting any irregularities, such as blockages or leaks, that could impair the system’s functionality, reducing energy consumption, and extending the lifespan of the chiller, ultimately leading to cost savings and enhanced operational reliability.