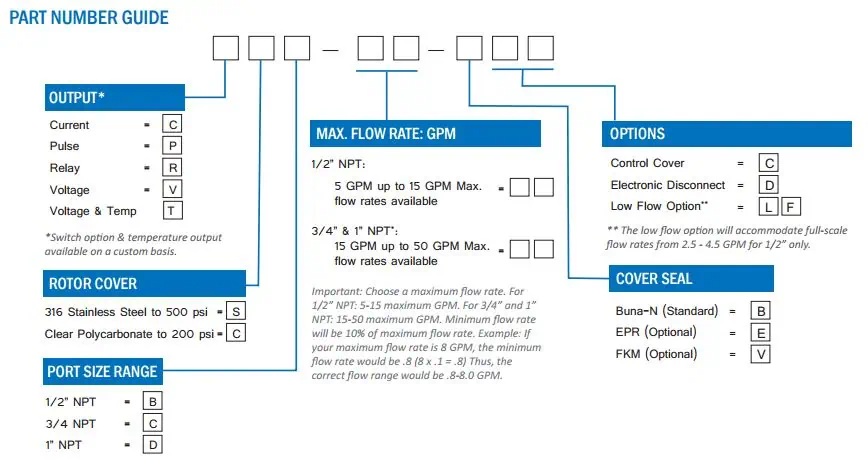

Choice of Three Port Sizes: Select from 1/2” , 3/4” or 1” NPT porting to meet system requirements. NOTE: Using reduced ID fittings will affect calibrated range.

Encapsulated Circuitry: Withstands the harshest environments.

Several Outputs Available: The standard interface is a 2-wire, 4-20mA current loop. Sensor signal may be transmitted on a low cost wire without degradation. Pulse, relay and 0-5 VDC (regulated) are also available.

Connects Directly to your Flow Monitoring Instruments: Can be connected directly to analog acquisition cards, chart recorders or other monitoring instruments, without external signal conditioning.

Simply Plumb and Apply Power: Comes factory calibrated to your flow range specifications.

±2.0% of full scale

±0.5% of full scale

1/2“ porting: 5–15 GPM (2–60 LPM)

1/2″ porting low flow option: 2.5-4.5 (10-17 LPM)

3/4″ – 1″ porting: 15–50 GPM (60–200 LPM)

10:1

Clear Polycarbonate Cover: up to 200 PSIG (14 bar)

With Optional Stainless Steel Cover: up to 500 PSIG (34 bar)

20-225°F (-7° to 107°C)

Water @ 70°F Temperature (21°C), 1.0 sg

150 micron filter recommended

Real-World Applications

Water Monitoring in Chiller System

Coolant in Welding Machine

Water Flow in Tankless Water Heater

Although onshore chemical injection systems are installed on land, at ground level, and in more stable conditions, they are still exposed to weather, varying temperatures, dust, and potential exposure to industrial pollutants. The JV-BB gear meter is still the best choice for its high accuracy and repeatability for consistently precise dosing of the valuable chemicals. Additionally, they handle a wide range of viscosities and flow rates.

Water Monitoring in Chiller System

Coolant in Welding Machine

Water Flow in Tankless Water Heater

Although onshore chemical injection systems are installed on land, at ground level, and in more stable conditions, they are still exposed to weather, varying temperatures, dust, and potential exposure to industrial pollutants. The JV-BB gear meter is still the best choice for its high accuracy and repeatability for consistently precise dosing of the valuable chemicals. Additionally, they handle a wide range of viscosities and flow rates.