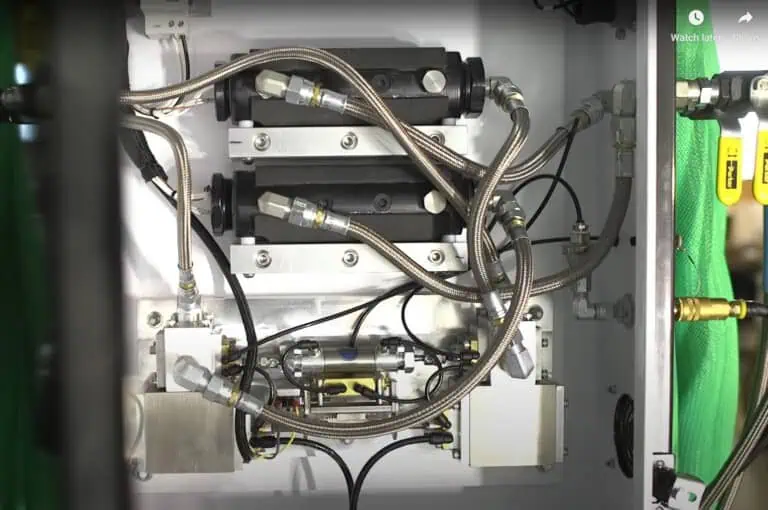

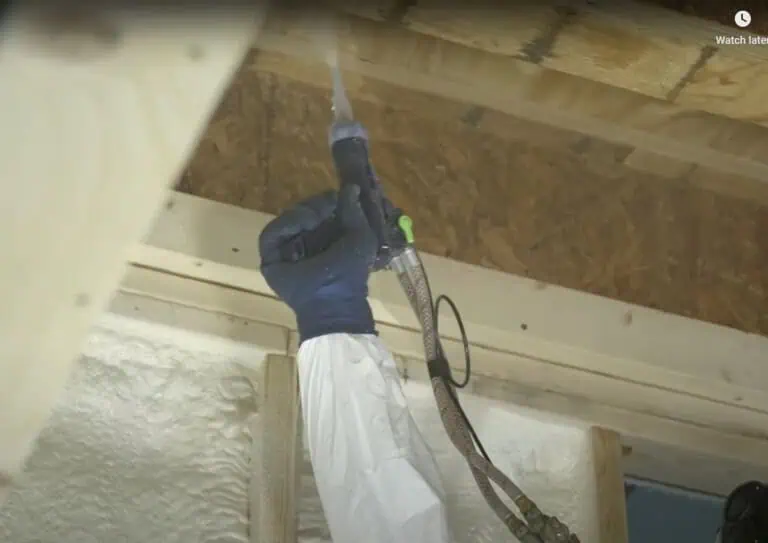

A manufacturer of spray polyurethane foam (SPF) equipment developed an automated, high-accuracy system for void-filling applications like taxidermy molds and boat hulls. The system uses a proportional pump to deliver chemicals from two drums to a spray gun, producing polyurethane foam. To maintain consistent, high-quality foam based on user-defined recipes, the manufacturer required a precise method for metering the chemical output.

Gear Meters

Gear meters specifically spur gear, are ideal for low flow rates, viscous fluids, and measurement of flows involving starts and stops or pulsing.