The LAKE Basic Inline Variable Area flow meter is ideal for monitoring pump performance and oil or water flows through hydraulic circuits and cooling systems. Often referred to as “rotameters,” Lake’s Basic meters are a low cost alternative to other flow meter types and are available in numerous materials of construction, including aluminum, brass and stainless steel to meet system and media requirements. The superior design not only makes this flow meter weather-proof for outdoor environments and wash-downs, but also reliable offering maintenance-free performance.

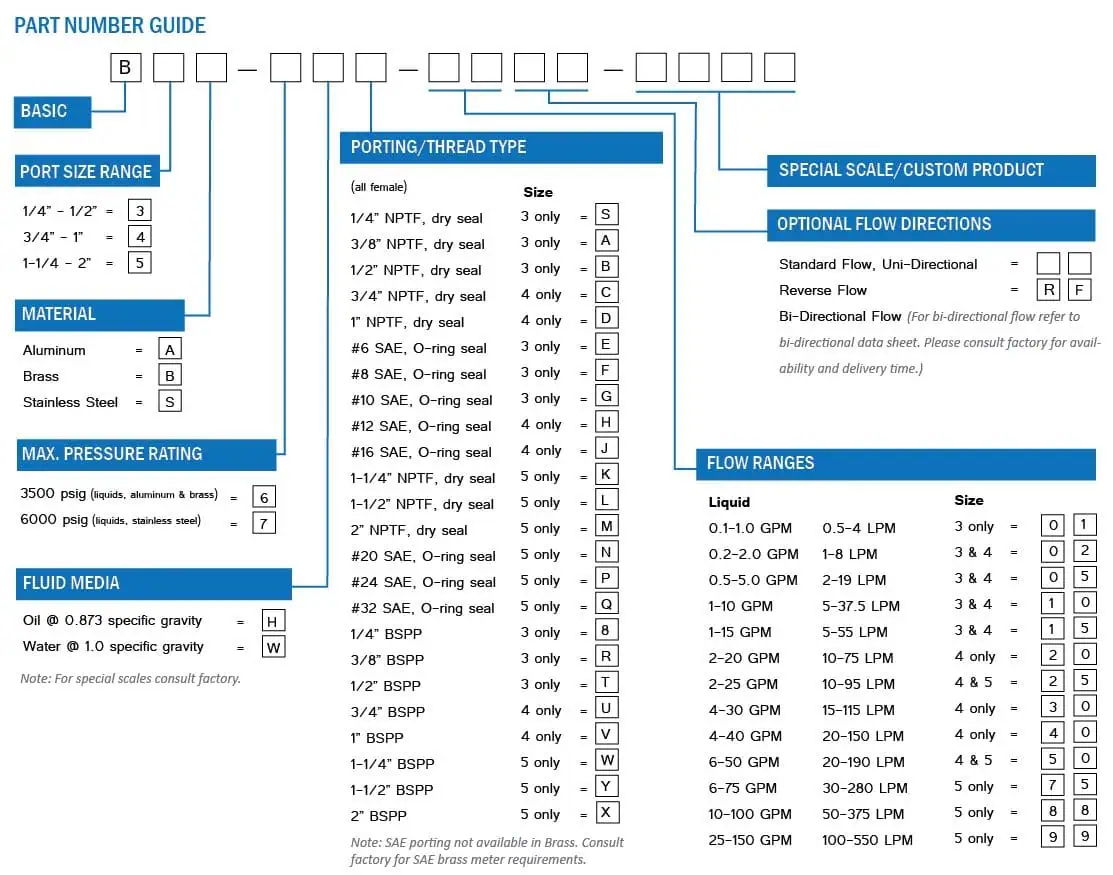

Choice of Three Materials of Construction: Select from aluminum, brass or stainless steel to meet system and liquid requirements.

Unrestricted Mounting: Allows for horizontal, vertical or inverted installation and does not require straight plumbing on inlet or outlet.

Superior Exterior Design: Weather-tight for use outdoors and/or on systems where wash downs are required.

Rugged and Reliable: Designed as a hydraulic service tool, this monitor will provide years of maintenance-free performance.

High Pressure Operation: The magnetically coupled follower design allows operation to 6000 PSIG and use with liquids.

Many Different Ports Available: Standard selection of NPT, SAE and BSPP ports reduces the amount of adapters required for installation.

±2.0% of full scale

±1% of full scale

0.1-150 GPM (0.5-550 LPM)

Aluminum and brass meters: 3500 PSIG (240 Bar), Stainless steel meters: 6000 PSIG (410 Bar)

240°F (116°C) Note: for operation to 600°F (316°C), see our High Temperature Data sheet.

Oil meters: DTE 25® @ 110°F (43°C), 0.873 sg

Water meters: tap water @ 70°F (21°C), 1.0 sg

74 micron filter or 200 mesh screen minimum

Window Tube: Polycarbonate

Window Seals: Buna-N, PTFE option

Casing & End Ports: Anodized Aluminum, Brass, or Stainless Steel

Seals: Buna-N, optional EPR, FKM, or FFKM

Transfer Magnet: PTFE coated Alnico

All other internal parts: Stainless steel

Configure Your Meter

Real-World Applications

Bearing Lubrication Monitoring

AW-Lake’s Basic Variable Area flow meters are crucial in measuring the flow of bearing lubrication to ensure that machinery operates smoothly and efficiently by maintaining optimal lubrication levels. These meters provide precise real-time data on lubricant flow, helping to prevent over-lubrication or under-lubrication, which can lead to bearing wear or failure. Industries such as automotive manufacturing, aerospace, and heavy machinery rely on these meters to monitor lubrication systems, ensuring the longevity and reliability of their equipment.

Hydraulic Fluid Monitoring

Basic VA flow meters play a crucial role in hydraulic fluid monitoring, ensuring the optimal performance and longevity of hydraulic equipment such as booms, saws, drills, augers, compactors, power packs, concrete hammers, and snow removal equipment. By providing precise measurements of hydraulic fluid flow, these meters help prevent damage from over- or under-pressurization, maintain efficient operation, and maximize the equipment’s performance and reliability across various applications.

Vehicle Power Steering Fluid

Flow meters are utilized in vehicle power steering systems to monitor the flow of power steering fluid, serving as a vital diagnostic tool. They help ensure the power steering system remains functional, allowing for quick identification of issues and minimizing vehicle downtime. This is particularly crucial in military vehicles deployed overseas, where a power steering failure can be potentially deadly for troops relying on safe transportation.

Bearing Lubrication Monitoring

AW-Lake’s Basic Variable Area flow meters are crucial in measuring the flow of bearing lubrication to ensure that machinery operates smoothly and efficiently by maintaining optimal lubrication levels. These meters provide precise real-time data on lubricant flow, helping to prevent over-lubrication or under-lubrication, which can lead to bearing wear or failure. Industries such as automotive manufacturing, aerospace, and heavy machinery rely on these meters to monitor lubrication systems, ensuring the longevity and reliability of their equipment.

Hydraulic Fluid Monitoring

Basic VA flow meters play a crucial role in hydraulic fluid monitoring, ensuring the optimal performance and longevity of hydraulic equipment such as booms, saws, drills, augers, compactors, power packs, concrete hammers, and snow removal equipment. By providing precise measurements of hydraulic fluid flow, these meters help prevent damage from over- or under-pressurization, maintain efficient operation, and maximize the equipment’s performance and reliability across various applications.

Vehicle Power Steering Fluid

Flow meters are utilized in vehicle power steering systems to monitor the flow of power steering fluid, serving as a vital diagnostic tool. They help ensure the power steering system remains functional, allowing for quick identification of issues and minimizing vehicle downtime. This is particularly crucial in military vehicles deployed overseas, where a power steering failure can be potentially deadly for troops relying on safe transportation.