The TN Turbine Flow Meter is a cost effective turbine meter that can withstand the demands of the most rigorous flow measurement applications. It is ideal for light viscosity fluids like water, glycol, or solvents and can also provide liquid flow measurement on or off the oilfield. These meters offer many benefits, including:

- Accuracy & Reliability: ±1% of reading

- Electronic Integration: This meter can accept a variety of existing electronics, including the EDGE sensor.

- Simplified Maintenance: Maintenance is easy with the rotor replacement kit. Rotor can be replaced in just 2-3 minutes.

- Rugged & Cost Effective: All stainless steel construction and tight machining tolerances make for excellent durability/long life.

- Compatible with Current Systems: Easy to install drop-in replacement of other brands of flow meters.

0.3 – 5,500 GPM (across all meter sizes)

Up to 5,000 psi

±1.0% over full range with 1cP fluid | ±2.0% for TN-0.5-3 and TN-103

±0.1% over full range

-100°F to 250°F (up to 850°F with special coil)

10:1

Water (NIST traceable)

NPT and Victaulic® Groove (consult factory for other options)

Body: 316 Stainless Steel

Rotor: 416 Stainless Steel (CD4MCu)

Rotor Supports: 316 Stainless Steel

Rotor Shaft: Tungsten Carbide

Sleeve Bearings: Tungsten Carbide

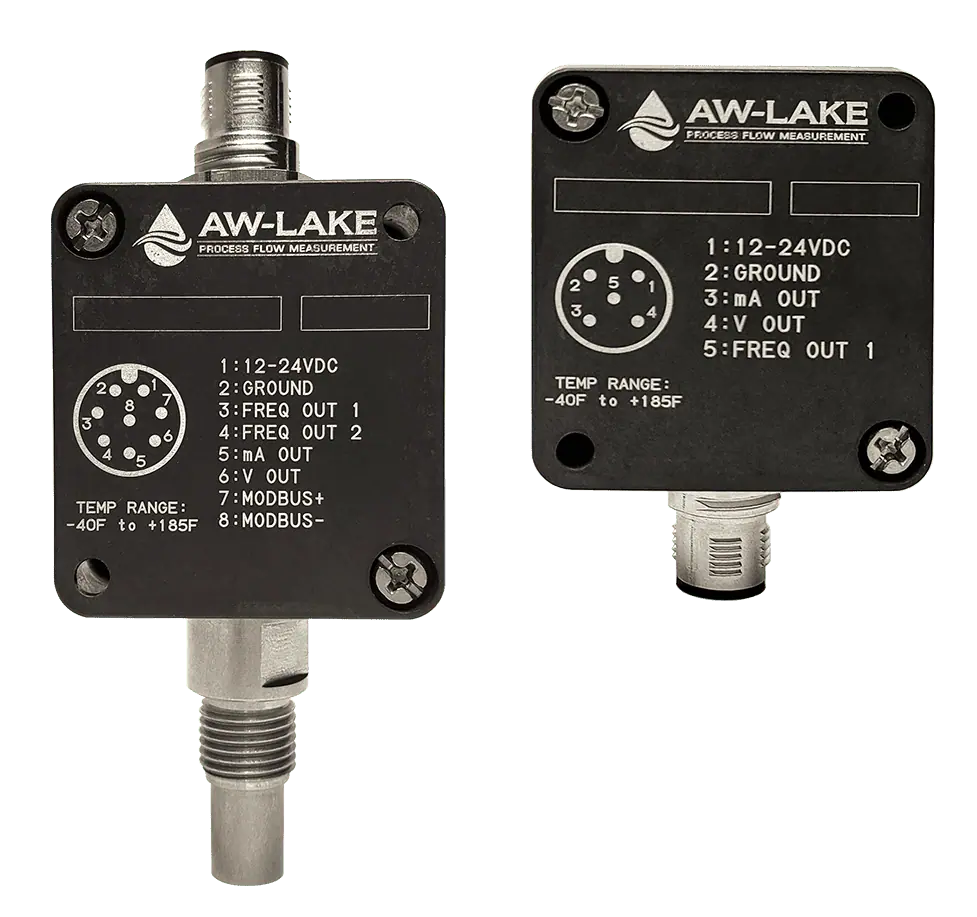

Included Sensor:

Pulse output

EDGE Sensor:

Pulse, analog, or Modbus outputs

Digital Display:

EX rated, flow rate & total, analog and pulse outputs

Real-World Applications

The TN turbine flow meter is essential in the onshore water separation systems at oil wells, where the water drained from the oil-water separators must be accurately measured. By providing precise flow data, these meters enable accurate billing and EPA reporting of the disposed water. This ensures cost-effective and efficient water management, reducing transportation and disposal expenses while meeting regulatory requirements.

The TN turbine flow meter is essential in the onshore water separation systems at oil wells, where the water drained from the oil-water separators must be accurately measured. By providing precise flow data, these meters enable accurate billing and EPA reporting of the disposed water. This ensures cost-effective and efficient water management, reducing transportation and disposal expenses while meeting regulatory requirements.