The sturdy construction of the TRG turbine flow meter means high performance and longer service life at an affordable price. This is the ideal flow meter for monitoring solvents and other lower viscosity fluids, such as antifreeze and fuels. With multiple flow ranges to choose from, this meter is suitable for many of the turbine flow measurement scenarios out there. This series was designed for easy cleaning and maintenance with only one moving part.

- Rugged & Cost-Effective: The sturdy construction of this turbine flow meter means high performance and longer service life at an affordable price.

- Industry Standard: The TRG Series flow meter comes with a standard NPT end connection for universal applications. Versatile This meter is capable of measuring flow in line sizes from 1/2” to 2”.

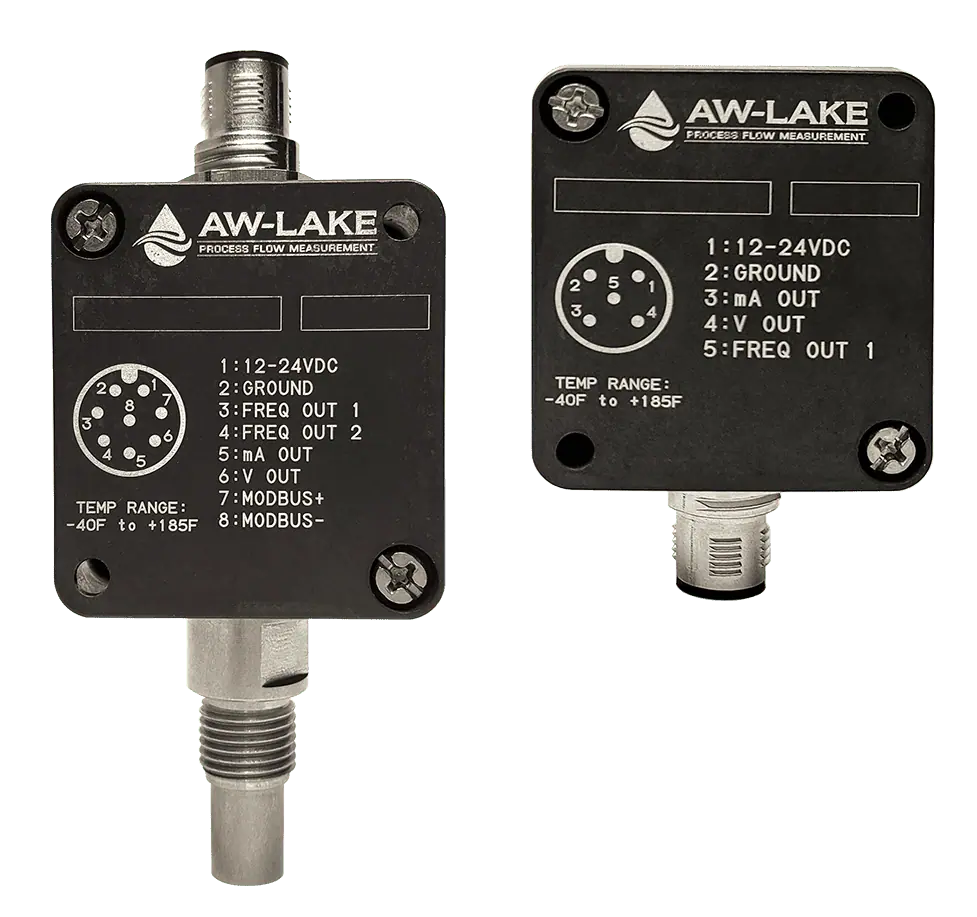

- Electronic Integration: This meter can provide displayed flow rate, totalization, current or voltage outputs through a variety of compatible electronics.

- Simplified Maintenance: The TRG Series was designed with only one moving part for easy cleaning and maintenance.

- Explosion Proof (EX) Options Available

± 1.0% of reading or better

± 0.1%

.08 to .4 GPM

.13 to 1.06 GPM

.3 to 3 GPM

.9 to 9 GPM

1.6 to 16 GPM

3.2 to 32 GPM

5.3 to 53 GPM

13 to 200 GPM

10:1

Working pressure up to 5,000 psi

Fluid temperature of -150° to 450°F

Tap water @ 70°F

NPT

Body: 316L Stainless Steel

Rotor Support: 303 Stainless Steel

Rotor Shaft: Tungsten Carbide

Impeller: 420 Stainless Steel

Real-World Applications

Engine Coolant Testing

The TRG Turbine paired with the EDGE sensor is ideal for powertrain test engineers testing vehicle performance while conducting coolant loop tests for the oil cooler, heater cores, head bleeds, and intercoolers of powesports engines. TRG Turbines provide an economical solution and the EDGE sensor’s Bluetooth interface allows for easy setup.

Cooling System in Recycling Facility

Turbine flow meters play a crucial role in the facility’s cooling system by measuring water flow in the “cold” and “hot” sides of the condenser heat exchanger. The TRG-11.25 turbine meter monitors the “cold” side, while the TRG-11.75 meter measures the “hot” side. These meters, integrated with sensors and converters, provide flow data to a PLC analog input channel. This data is then used within PLC logic to establish flow parameters, ensuring precise process control of the heat exchange system.

Fire Retardant Foam on Fireboats

TRG turbine flow meters are essential on fireboats for accurately dispensing foam to extinguish fires. The foam, mixed with water via a 3-way selector valve controlled by PLC logic, requires precise flow measurement to maintain a target ratio of 3% foam by volume. AW-Lake TRG-11.500 (½”) and TRG-1110 (2”) Turbine Flow Meters monitor foam flow, ensuring accuracy despite the foam’s low viscosity.

Commercial Brewing – Straining Process

The TRG turbine flow meter is vital in brewing, monitoring hydraulic fluid in a robotic rake that settles mash at the vessel’s bottom. It ensures high accuracy and repeatability over a wide flow range, maintaining uninterrupted rake movement and consistent product quality. This precision enables the effective and efficient separation of liquid from solid material during the brewing process.

Engine Coolant Testing

The TRG Turbine paired with the EDGE sensor is ideal for powertrain test engineers testing vehicle performance while conducting coolant loop tests for the oil cooler, heater cores, head bleeds, and intercoolers of powesports engines. TRG Turbines provide an economical solution and the EDGE sensor’s Bluetooth interface allows for easy setup.

Cooling System in Recycling Facility

Turbine flow meters play a crucial role in the facility’s cooling system by measuring water flow in the “cold” and “hot” sides of the condenser heat exchanger. The TRG-11.25 turbine meter monitors the “cold” side, while the TRG-11.75 meter measures the “hot” side. These meters, integrated with sensors and converters, provide flow data to a PLC analog input channel. This data is then used within PLC logic to establish flow parameters, ensuring precise process control of the heat exchange system.

Fire Retardant Foam on Fireboats

TRG turbine flow meters are essential on fireboats for accurately dispensing foam to extinguish fires. The foam, mixed with water via a 3-way selector valve controlled by PLC logic, requires precise flow measurement to maintain a target ratio of 3% foam by volume. AW-Lake TRG-11.500 (½”) and TRG-1110 (2”) Turbine Flow Meters monitor foam flow, ensuring accuracy despite the foam’s low viscosity.

Commercial Brewing – Straining Process

The TRG turbine flow meter is vital in brewing, monitoring hydraulic fluid in a robotic rake that settles mash at the vessel’s bottom. It ensures high accuracy and repeatability over a wide flow range, maintaining uninterrupted rake movement and consistent product quality. This precision enables the effective and efficient separation of liquid from solid material during the brewing process.

We work with you to increase process efficiency, reduce costly production down-time, establish real-time monitoring and control, and provide the critical tracking and record keeping necessary to meet EPA regulations.

Application Stories