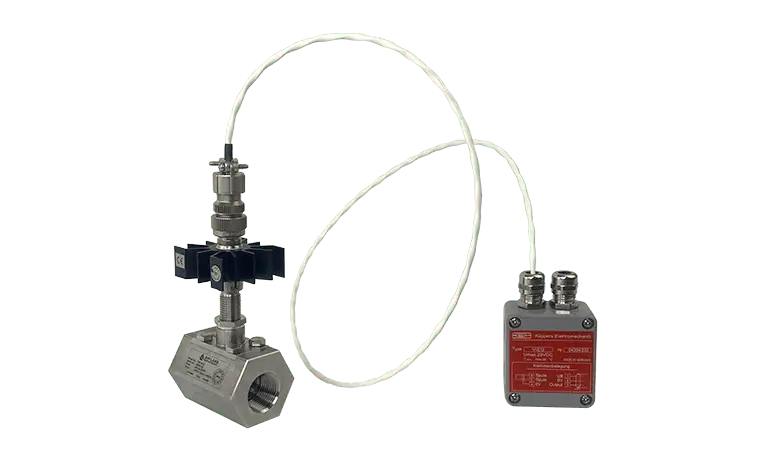

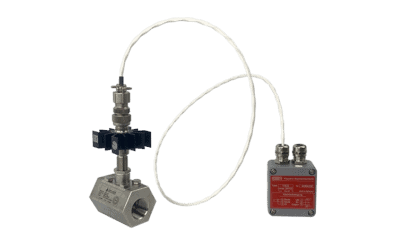

The TRP High Temperature Turbine Flow Meter was designed specifically to integrate into high temperature heat transfer loops often associated with maintaining ideal temperatures in the metal die casting industry. Maintaining consistent mold temperatures ensures controlled curing and optimum mold release of cast parts with reduced cycle times. With accuracies of 2.5% and repeatability of 0.5% the TRP High Temperature Turbine Flow Meter delivers the accuracy required in even the toughest applications with contaminated or extremely hot oil heat transfer media.

Meter

± 2.5% of actual flow

± 0.5%

.75 to 7.5 GPM

2.5 to 25 GPM

4.0 to 40 GPM

7.5 to 75 GPM

1/2″ through 1″

NPT

Fluid temperature of -76° to 662˚F | -60° to 350˚C

Working pressure up to 290 psi | 20 bar

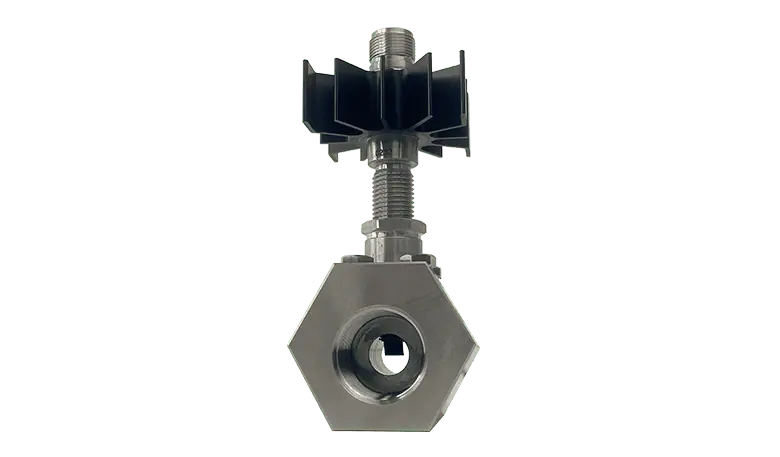

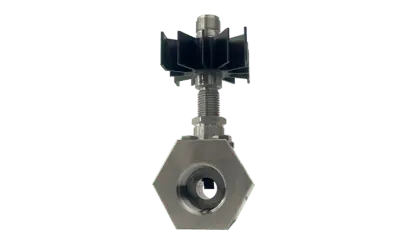

Body: 303 Stainless Steel

Wheels: Stainless Steel (DIN 1.4122)

Bearings: Brass

Seals: Graphite

Sensor

0.5 mV to 500 mV (Passive coil – amplitude is flow dependent)

7 to 820 Hz depending on flow meter

MIL 3-pole

Stainless steel

Real-World Applications

Temperature Control in Metal Die Casting

In die casting cooling circuits, TRP turbine flow meters are used to monitor and control the flow of cooling fluids, ensuring efficient thermal management during the casting process. Accurate flow measurement helps maintain the proper temperature of the molds, preventing overheating and ensuring consistent quality of the cast parts. TRP turbine meters enable precise adjustment of cooling parameters, optimizing the cooling cycle and enhancing the overall efficiency of the die casting process.

Temperature Control in Metal Die Casting

In die casting cooling circuits, TRP turbine flow meters are used to monitor and control the flow of cooling fluids, ensuring efficient thermal management during the casting process. Accurate flow measurement helps maintain the proper temperature of the molds, preventing overheating and ensuring consistent quality of the cast parts. TRP turbine meters enable precise adjustment of cooling parameters, optimizing the cooling cycle and enhancing the overall efficiency of the die casting process.