Chemical Measurement for High and Low-Pressure Injection

Chemical injection systems are used globally on oil production platforms to improve the speed, efficiency, and security of hydrocarbon extraction and processing. They rely on autonomous chemical measurement and dosing to inject distinct chemical mixtures directly into oil flow lines and inhibit the build-up of particulate matter. This is complicated by the inherently harsh environment of offshore oil production environments. Components must withstand severe weather, salt water, and galvanic corrosion, extremely low temperatures and high pressures when utilized at depth. Especially challenging is the nature of the extracted material itself, which can be problematic for oil flow lines and injection systems.

Typical offshore platforms are comprised of an artificial island connected to multiple subsea oil wells via umbilical connections. These flow lines are used to transport crude extractions from the seabed to the topsides equipment and the production terminal, where production fluids are processed into viable petroleum. This is complicated by the fact that these fluids vary greatly in composition and viscosity, often comprising: processed water; natural gas; hydrocarbons of varying API gravity; and corrosive sour gases such as hydrogen sulfide (H2S).

The composition and flow rate of produced fluids, alongside the pressure range at the specific injection point of the flow line, determines the chemical mixtures and chemical measurement equipment required to ensure optimal start-up and ongoing production of extracted hydrocarbons.

Purpose of Chemical Injection

Typical chemical measurement functions in oil platforms include high flow rate methanol injection at subsea pressures to mitigate the formation of undesirable hydrates. Hydrate formation can cause solid slurries to build-up in oil lines, impacting flow rates and causing operational problems. Chemical measurement may also be used to control the rate of injection for diluents and biocides, both subsea and topside. This requires flow meters capable of performing both high and low-pressure injection. Additional chemical additives include paraffin, corrosion, and ice inhibitors, anti-foaming agents, and H2S scavengers.

AW-Lake flow meters have already demonstrated the requisite functionalities for improving throughput, cost-control, and oil quality using oil flow injection systems.

Oil Flow Lines and Chemical Measurement: An Application Story

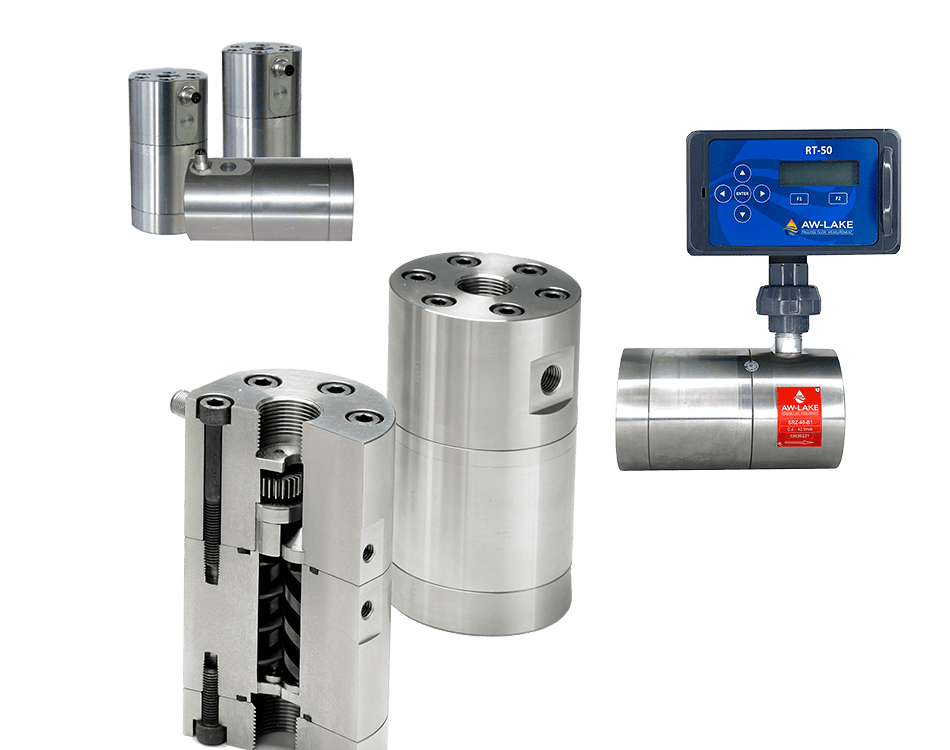

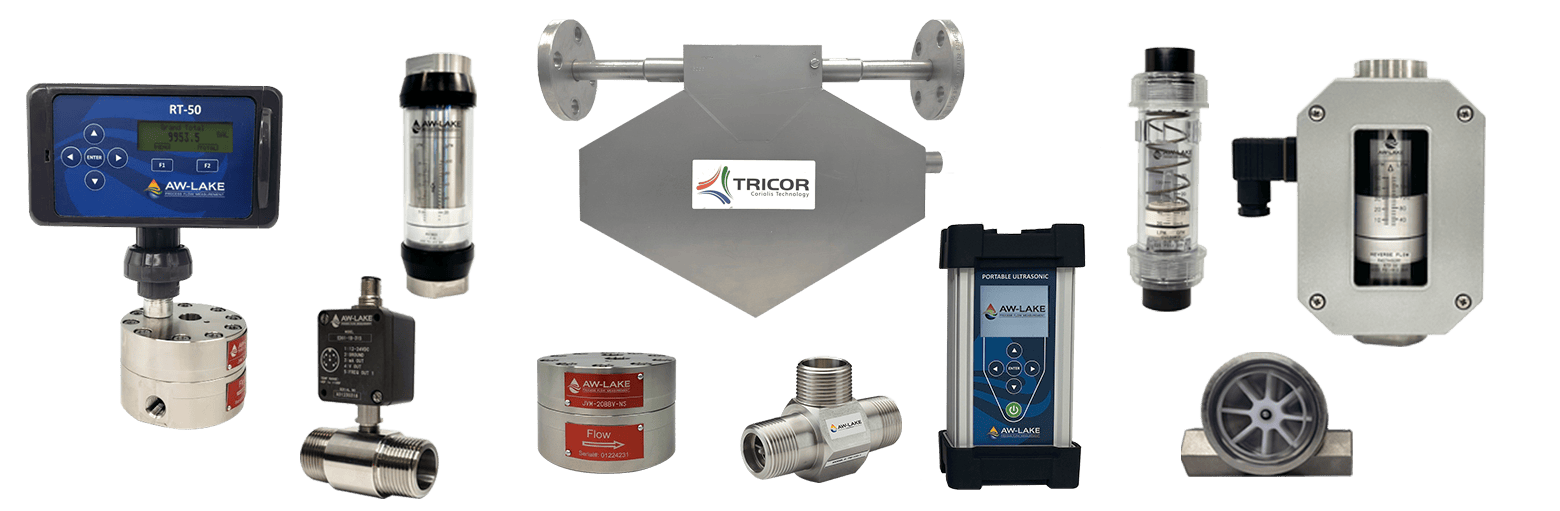

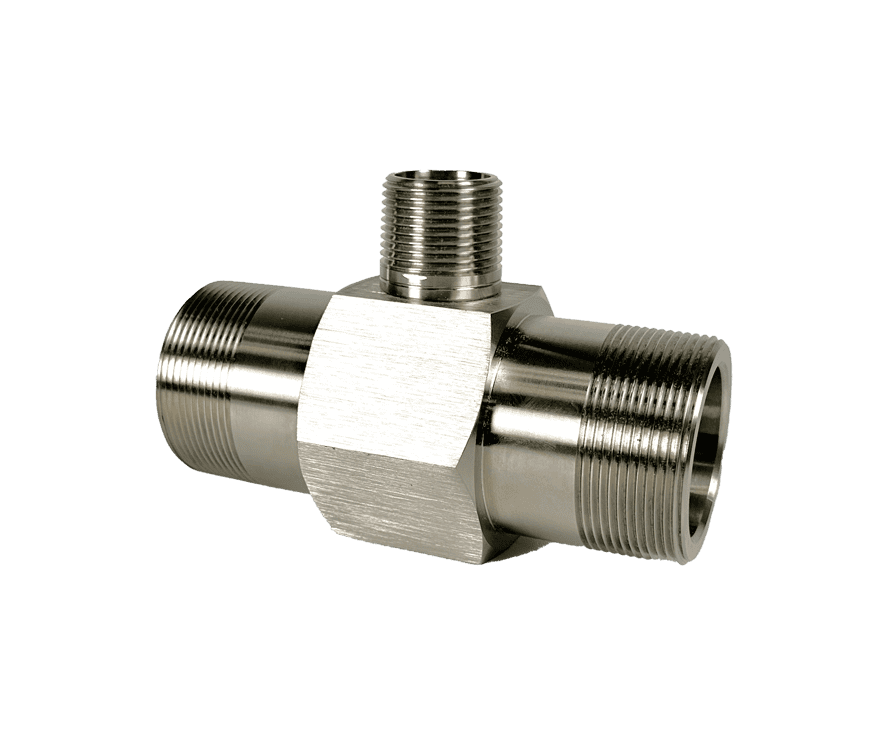

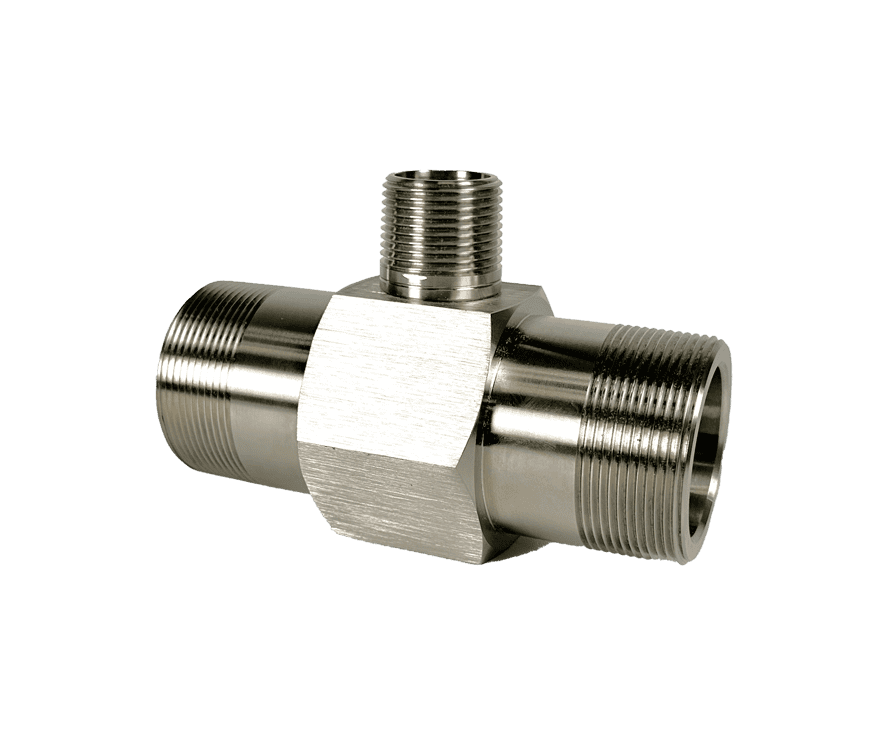

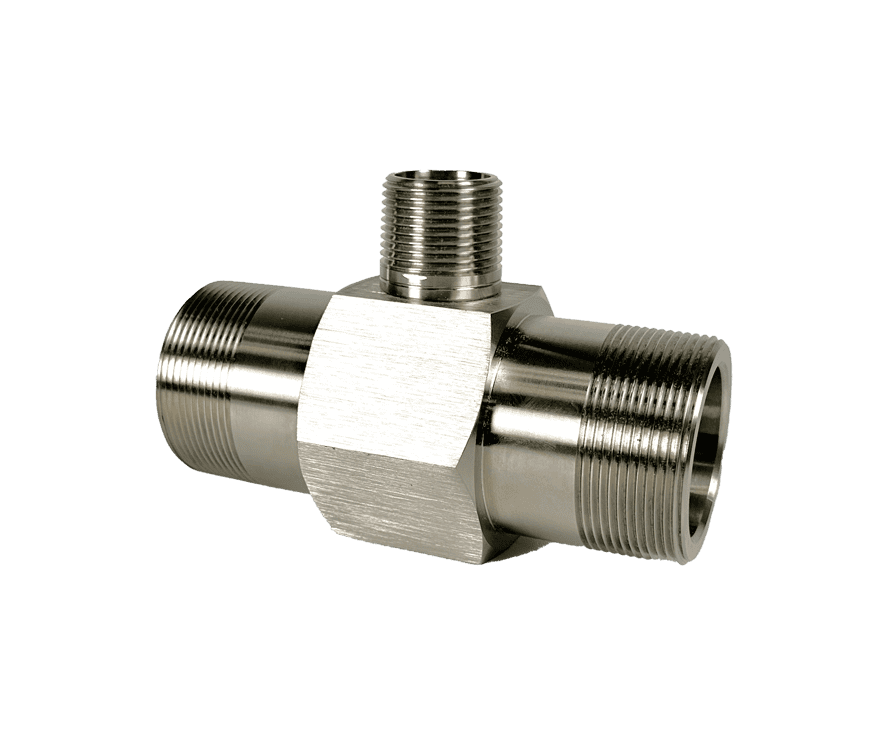

AW-Lake has provided a variety of high- and low-pressure flow meters for chemical injection skids to be installed on offshore oil production platforms in the Gulf of Mexico. The complex chemical injection system includes multiple points and components requiring close chemical measurement.

Eighty distinct injection points on the chemical skids must be monitored for flows ranging from 2 – 15 gallons-per-minute (gpm) and pressures from 450 – 15,000 pounds per square inch (psi). This is complicated by the fact that fluid mediums are typically non-uniform in terms of composition and viscosity, which could cause blockages or corrosion to the interior of a flow line.

The client used several products to construct the injection system, including high- and low-pressure components. It was also necessary to provide chemical treatment of post-recovery oil and produced water once they reached the topsides system.

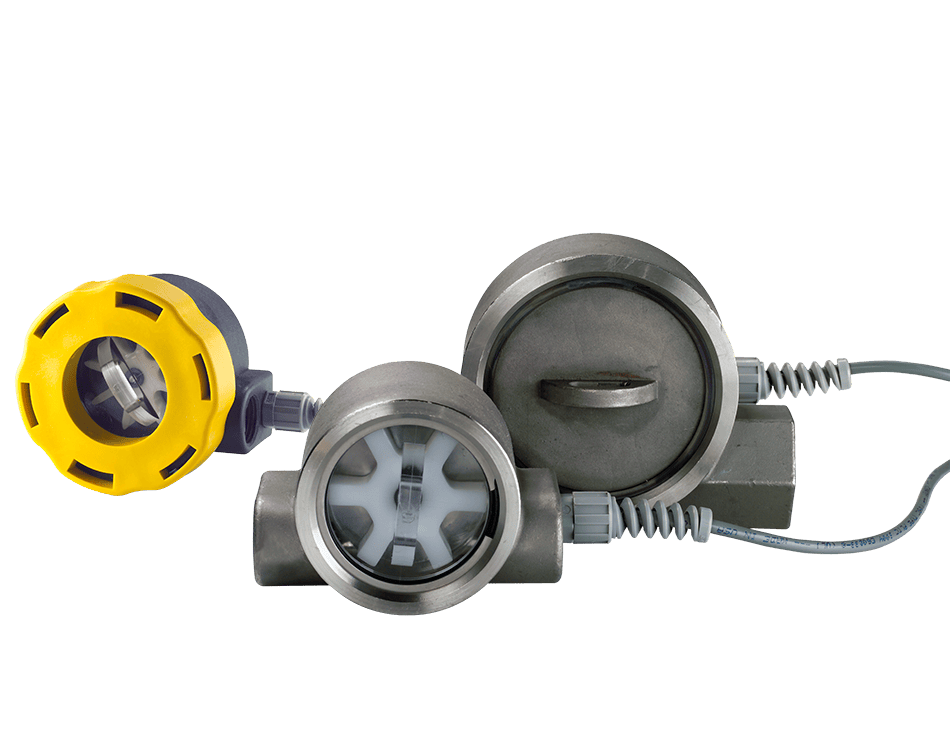

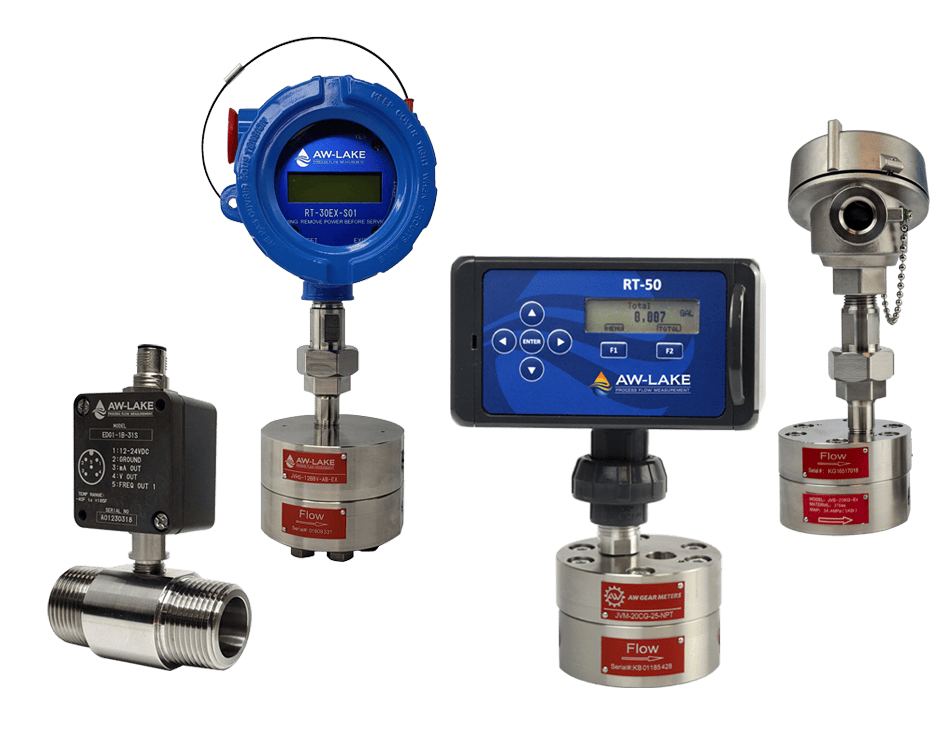

While providing a chemical injection system that enhances the performance of oil extraction and production was crucial for reducing operating expenditure and enhancing the oil yield, it also required highly precise chemical measurement to ensure optimal injection of high-value chemical agents. AW-Lake’s HM Series turbine flow and AW Gear Meters performed exceptionally well in both respects, providing unique chemical measurement solutions for injection points with distinct conditional requirements.

Chemical Measurement with AW-Lake

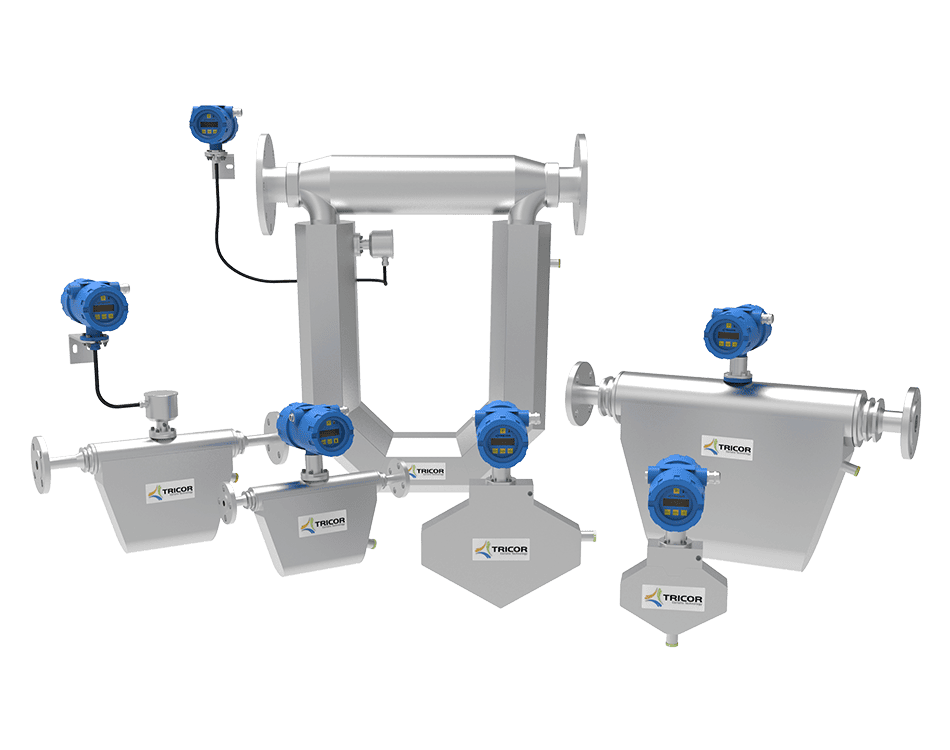

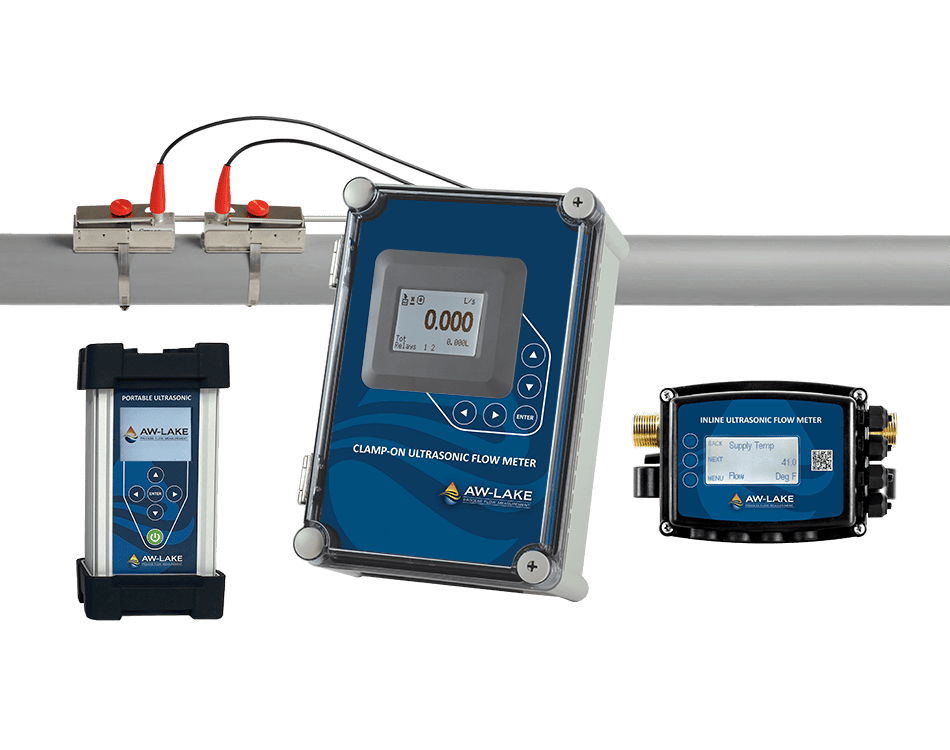

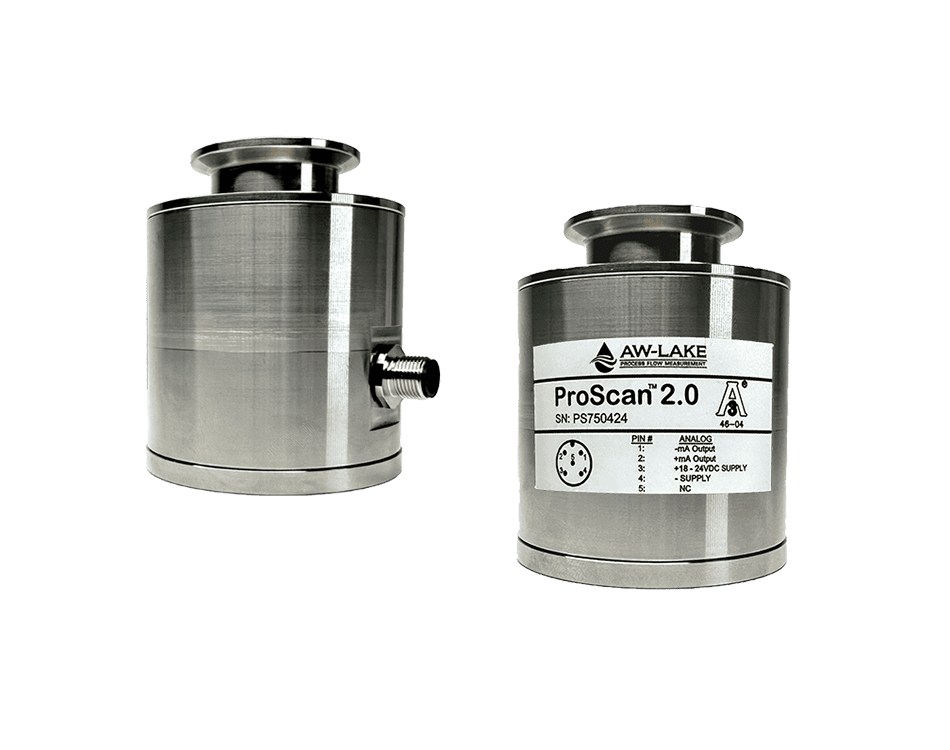

AW-Lake is one of the USA’s leading suppliers of flow measurement technology solutions for demanding areas of application. We provide an extensive range of systems and equipment for chemical measurement and fluid control, including axial turbine flow meters and positive displacement gear meters.

If you would like more information about chemical measurement in oil flow injection systems, feel free to read the full application story: High and Low Pressure Offshore Chemical & Methanol Injection.

Otherwise, contact us directly if you have any more questions.

Stay Up to Date With Everything AW-Lake

TASI Measurement Modernizes Brand to Match Innovation in Instrumentation