Paint Measurement: Importance of Ratio Control for Automotive Coatings

Besides body sheet metal, automotive plastics represent the largest sector of painted components on today’s sedans, SUV’s, and trucks. Yet but these dissimilar substrates require vastly different paint measurement and application processes.

Automotive Sheet Metal: Coatings and Paint Measurement

Automotive sheet metal coating systems typically comprise multiple, one-component coatings that impart the superior corrosion protection expected from modern vehicles. Car bodies are “dipped” in an e-coat tank containing an electrostatically charged liquid that, when dried, serves as the first layer of corrosion protection.

Bodies are then conveyed to the paint booths where primer, base coat, and the clear top coat are applied. Some automotive companies utilize powder primer applications in place of liquid primer application. Each method serves a vital role in preparing the surface for the base coat. When dry, it also serves as a barrier to harmful UV exposure that degrades adhesion to the e-coat. Today, most base coats are direct-charge water-borne, followed by two layers of clear coat.

Afterwards, the paint is cross-linked (cured) in a high-temperature oven that would melt and/or deform most automotive plastics.

Coating and Paint Measurement for Plastic Components

Plastic components are subsequently painted differently. Paint companies exploit a chemical reaction to promote molecular cross-linking so that coated parts can bake at roughly half the temperatures used for sheet metal. This chemical reaction is achieved by mixing a catalyst that reacts with the resin component. Holding the ratio of resin to catalyst to close tolerances during paint measurement is essential for optimum performance. Too little catalyst and the paint won’t cure properly Too much, and finished parts will be less resistant to stone chips and more prone to cracking. Both defects lead to costly warranty repairs.

The “pot life” is another important consideration. Once the two components are mixed, the chemical reaction begins, and the coating must be applied in a relatively short window as the viscosity steadily increases. At some point, the paint is unusable and can even solidify in paint lines and application equipment. None of these situations is desirable, so the industry requires on-demand 2K mixing solutions that deliver precise ratio and flow control for plastic coatings.

Automotive Coatings and Paint Measurement

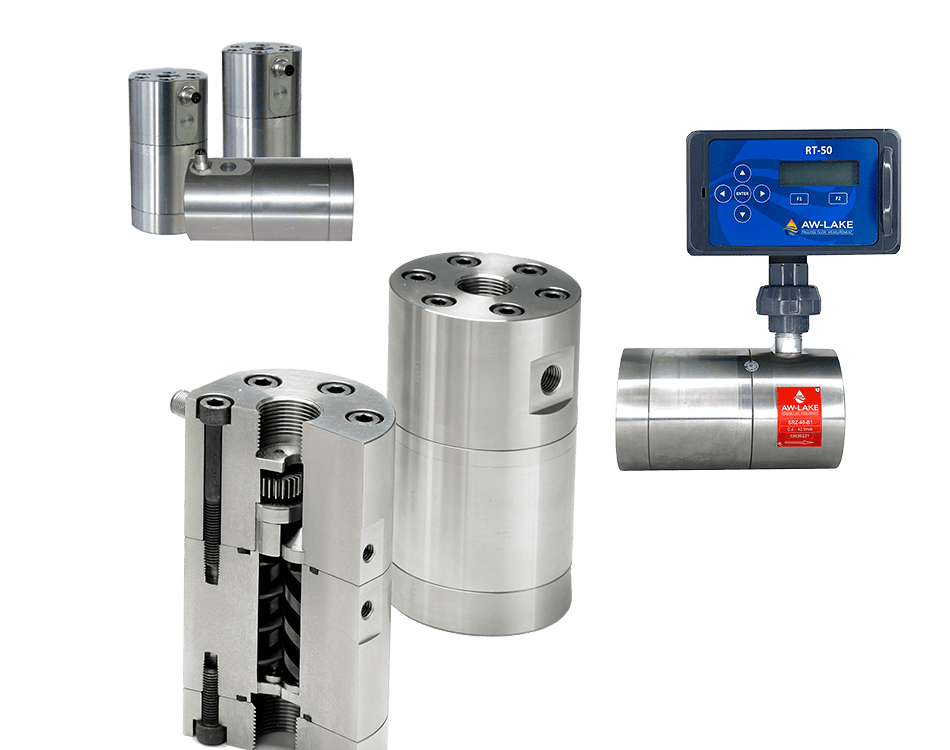

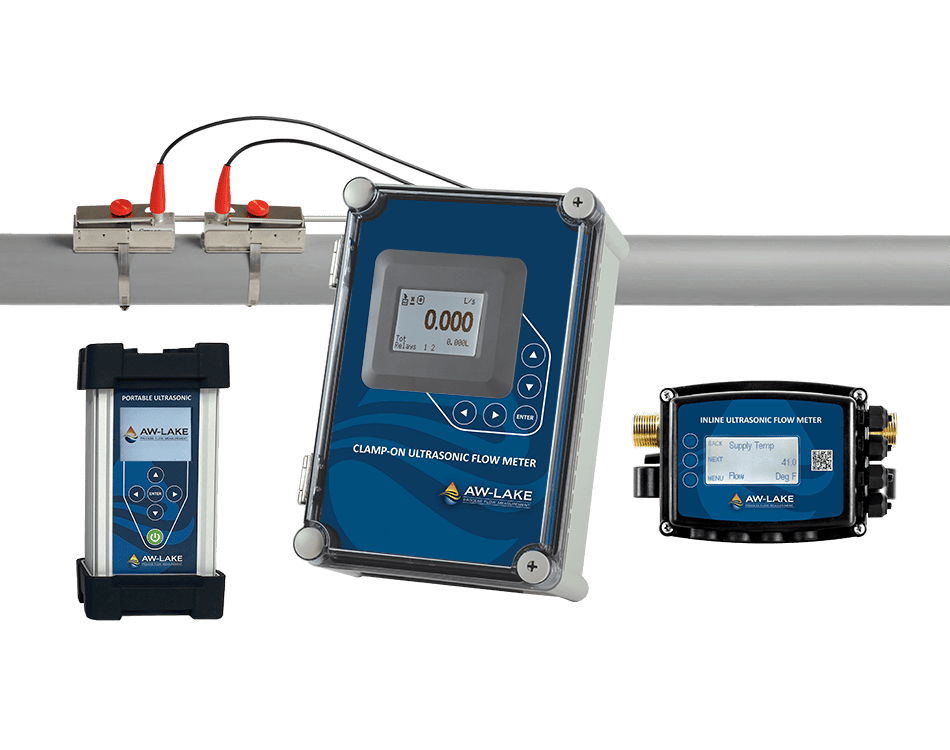

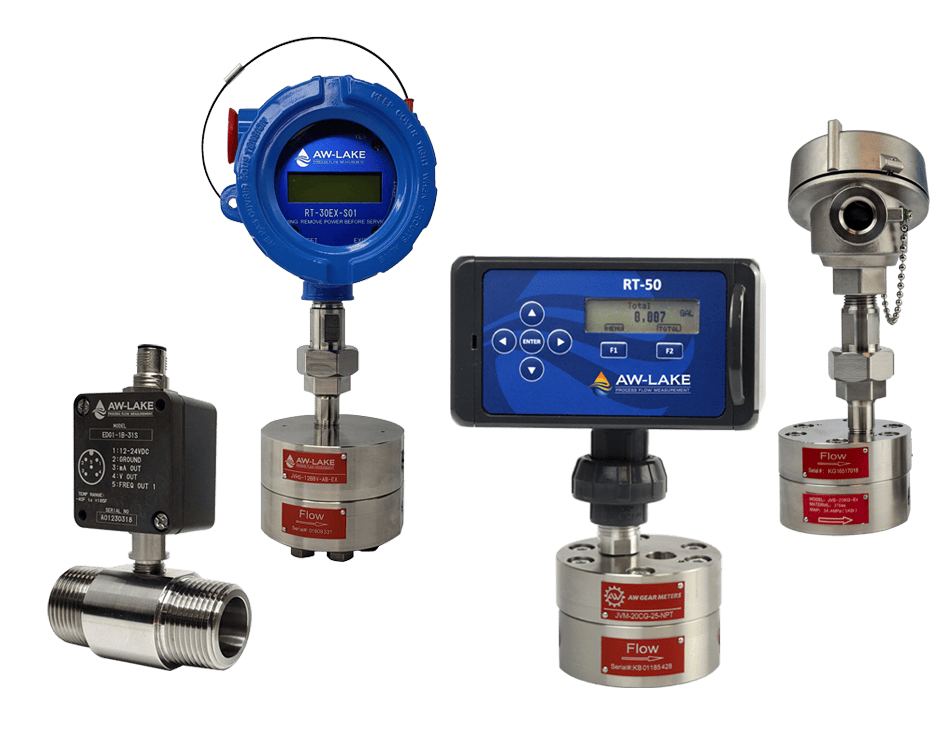

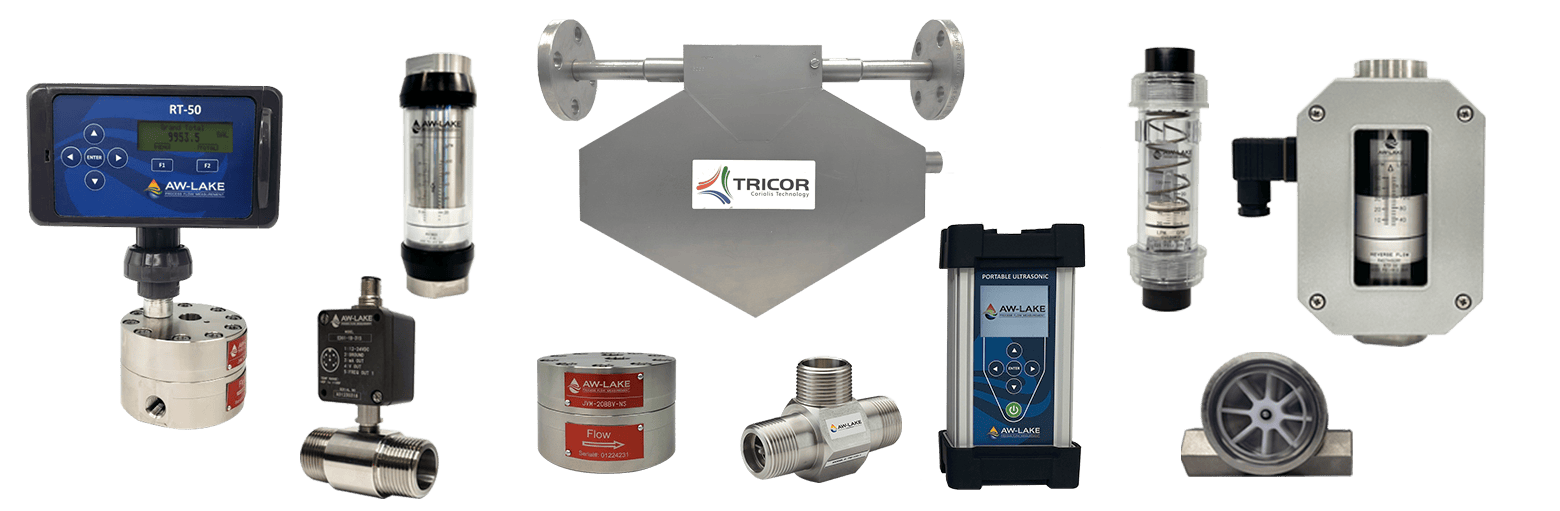

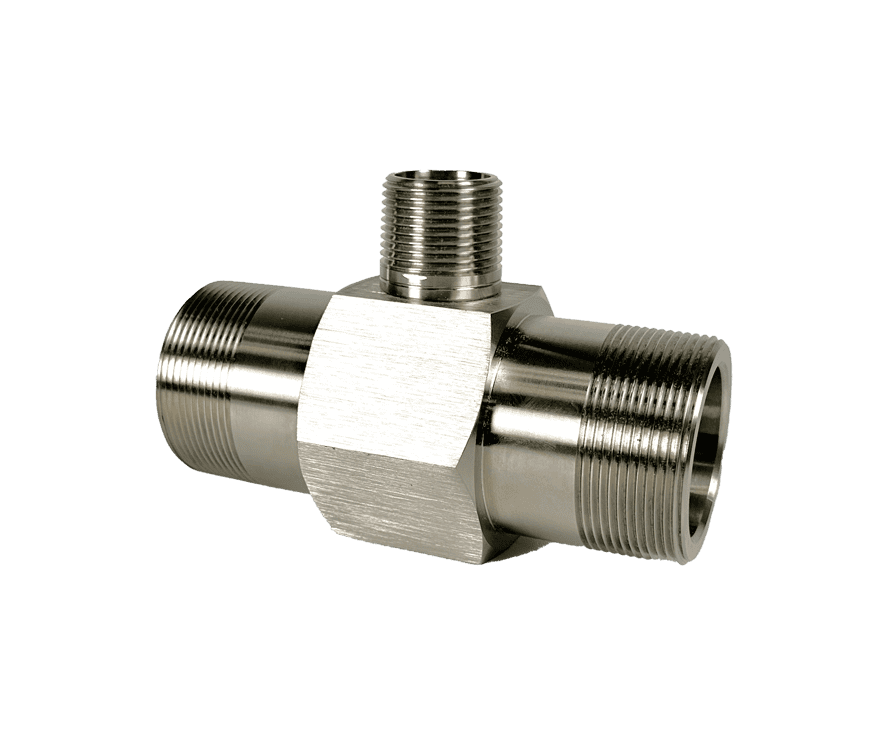

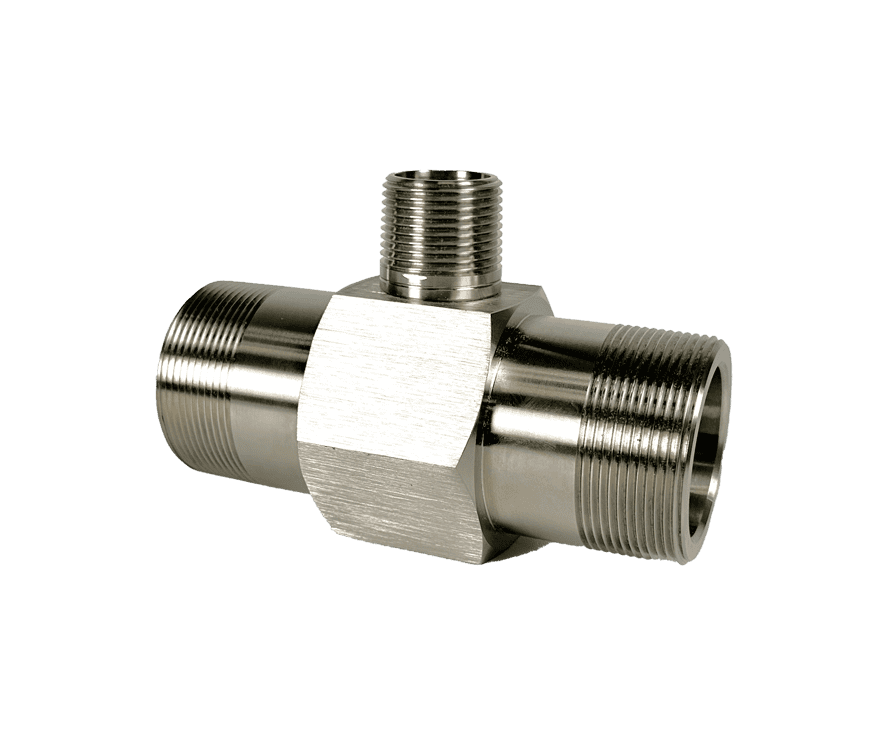

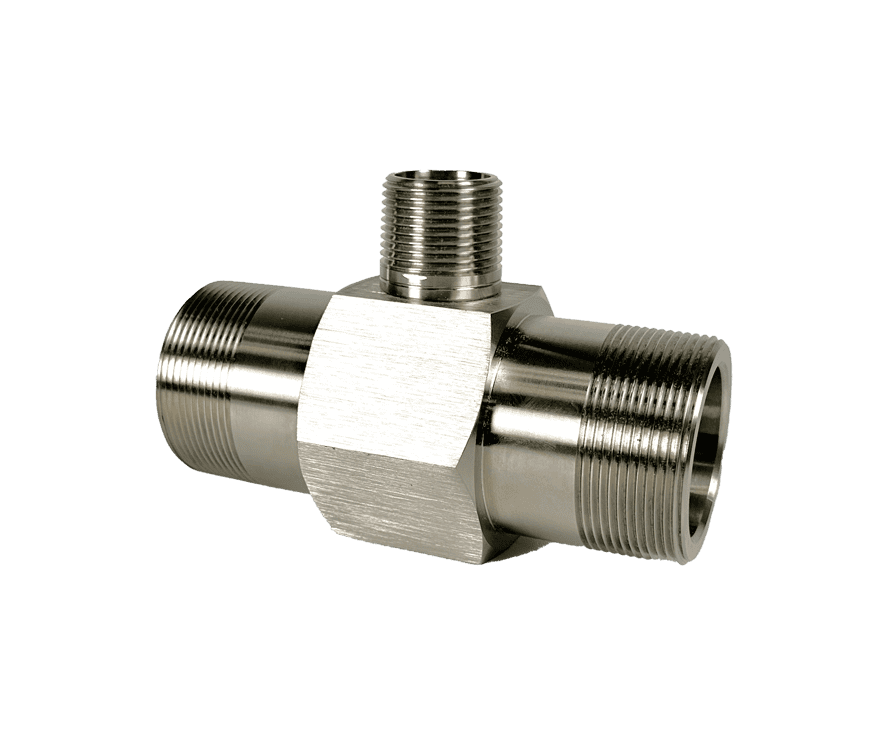

To overcome these application challenges while fulfilling the requirement of precisely-ratioed on-demand 2K coatings, equipment companies have devised multiple strategies. Some use gear pumps mounted in robot arms or on panels that feed the robot mounted applicators. The robots drive servo motors that turn the gear pumps at the exact RPM required to deliver the desired ratio which is an “open loop” process as there is no flow verification. When verification is required, an AW-Lake JVM-15CG or JVS-15SLGFS flow meter can be incorporated in the paint measurement and delivery system. With accurate flow feedback, the robot flow control system knows that ratios are within tolerances. Further, this data can be archived so that if down the line there is a warranty issue, the manufacturer has data that at least the application was within specifications leading to better defect analysis.

For smaller Tier-1 plastic component supplies, the gear pump solution is too costly. For these and companies that require human painters, other solutions are preferred. These systems utilize AW-Lake JVM-CG flow meters and various flow controlling regulators to meter the correct proportions of resin and catalyst to optimum tolerances. If the flow rates or ratios go out of tolerance, the “smart” 2K equipment will fault and notify the operator to the issue.

Paint and Coating Measurement with AW-Lake

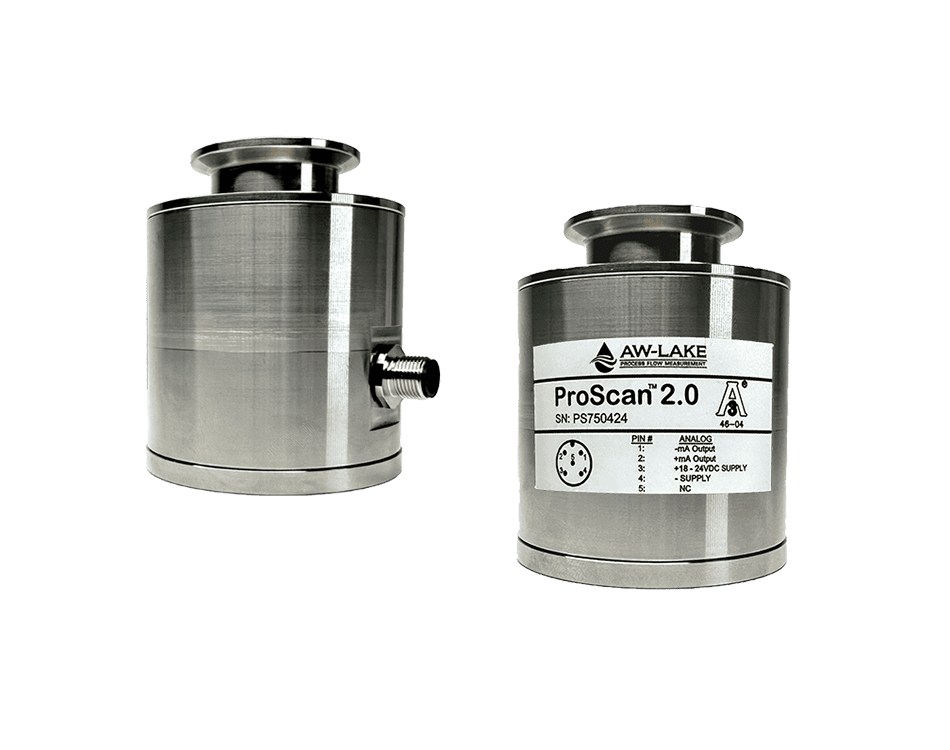

AW-Lake specializes in the development and supply of advanced flow metering solutions for demanding industrial applications. We have engineered a robust line of flow meters for coating and paint measurements in the automotive sector. These have been designed with harsh paint and coating media in mind, to improve the qualities of end-product automobiles and reduce assembly costs.

If you would like more information about performing paint measurement with AW-Lake, please do not hesitate to contact us directly.

Stay Up to Date With Everything AW-Lake

TASI Measurement Modernizes Brand to Match Innovation in Instrumentation