HM-AC High Pressure Turbine Flow Meter

The HM-AC series of turbine flow meters is ideal when measuring the flow of fluids under high pressure, such as in hydraulic testing. It is also perfect for chemical injection systems, as it withstands pressures up to 20,000 psi and is available in a variety of flow ranges (0.08 to 32 gallons/minute). Standard process connections are AutoClave®, but are also available in Grayloc® and Techlok®. A complete line of hazardous area approved sensors and displays are available as well.

- Industry Standard: Standard end connections are AutoClave®, (also available in Grayloc® and Techlok®.)

- High Pressure Suitable: The HM-AC Series of turbine flow meters can handle low viscosity fluids flowing under extremely high pressures, such as hydraulic and fuel systems and offshore chemical injection systems.

- Hazardous Area Approved Sensors: A complete line of hazardous area approved sensors and displays are available for the HM Series meters.

- Durable & Cost-Effective: This meter’s rugged stainless steel construction provides a durable and economic flow metering solution to sanitary environments.

- Explosion Proof (EX) Options Available

± 1.0% of reading or better

± 0.05%

.08 to .4 GPM

.13 to 1.05 GPM

.2 to 1.6 GPM

.3 to 2.6 GPM

.5 to 5 GPM

.9 to 9 GPM

1.6 to 16 GPM

2.25 to 22.5 GPM

3.2 to 32 GPM

10:1

Working pressure up to 20,000 psi

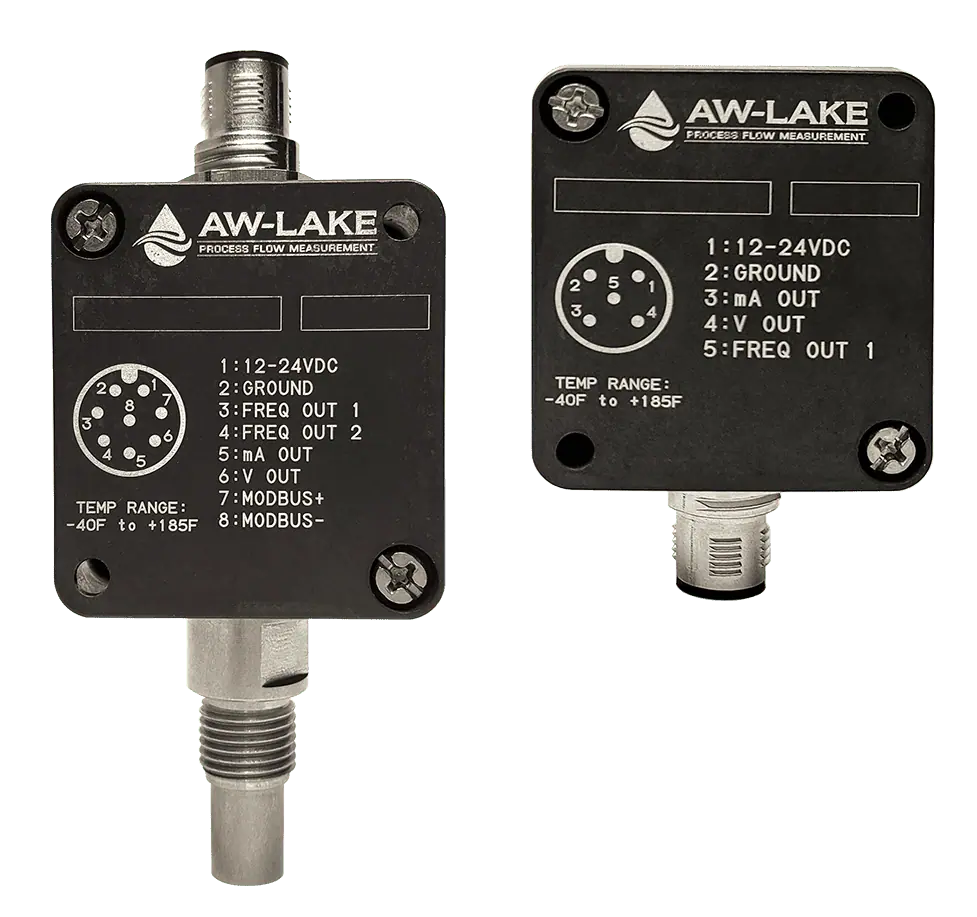

Depends on sensor used, refer to sensor page

300 microns

Medium pressure AutoClave®

Body: 316 Ti Stainless Steel

Rotor Support: 316 Ti Stainless Steel

Rotor: 329 Stainless Steel

Bearings/Shaft: Tungsten Carbide

Real-World Applications

Offshore Chemical Injection