AW-Lake’s Water Inline Ultrasonic Flow Meter was designed to accurately measure the flow of water and water glycol solutions in small pipes from ½” – 2½” in diameter. The no-moving-parts design operates over a wide flow range with excellent low flow accuracy. The low-cost design is provided with threaded process connections, a 4-20mA analog output and a scaled dry contact pulse output for totalization, as well as Modbus RTU. Units are available with and without a detachable LCD display, which can be mounted up to 5 feet away from the flow meter body for convenience.

FEATURES:

• Reliable No-Moving-Parts Design for Long Term Reliability

• High Accuracy Over a Wide Flow Range: ±1% of Reading over Normal Range (25:1), ±2% of Reading over Extended Range (100:1)

• User-Friendly Backlit Display and User Interface

• Detachable Display for Remote Mount Installation up to 5 Feet from the Sensor Body

• Built-In Interval Data Logger for Easy Data Access via Modbus

• ANSI/NSF 61 & 372 Approval

The Water Inline Ultrasonic meter incorporates a pair of wetted ultrasonic transducers that face each other directly in the flow tube. This configuration maximizes signal strength and

long-term reliability.

The flow tube design and direct beam path configuration is optimized for water and water/glycol solutions. This allows for improved accuracy at low flows.

The LCD Display version comes standard with Modbus RTU communications for instantaneous flow rate, volume total, run hours, and diagnostic information.

The Water Inline Ultrasonic meter has an innovative flow tube design that simplifies installation by allowing for limited straight pipe upstream and downstream of the meter in most installations.

Each Water Inline Ultrasonic meter is fully configured and programmed before it leaves the factory and is ready for use upon delivery.

IP67 (NEMA 6) rating allows for safe operation during temporary periods of submergence.

±1.0% of reading over 25:1 turndown

±2.0% of reading over 100:1 turndown

±0.2%

500:1 turndown

½”, ¾”, 1″, 1¼”, 1½”, 2″, and 2½”

Direct beam path wetted ultrasonic sensors utilizing differential transit time velocity measurement.

½” through 2”: Male NPT threads

2½”: ANSI Class 150 raised face flanges

Fluid: 32°F to 250°F (0 to 121°C)

Ambient: -13°F to 131°F (-25 to 55°C)

400 PSI | 27.6 bar

Less than 1 PSI at 4 ft/s, decreasing at lower velocities

20-28V AC/DC; 50/60 Hz, 5 VA maximum

May be programmed for flow rate or temperature. Configurable as 4-20mA (non-isolated). Optional 0-5 V or 0-10 V output.

May be programmed for volume, alarm indication, or Modbus coil indication.

Contact Ratings: 50mA, 30 VDC max.

Contact Pulse Duration: 1000 ms

Optional: Contact pulse duration (50, 100, or 500 ms)

For use with sinking open collector or dry contact outputs.

Input rating: 30 VDC, 10 mA maximum

Pulse duration: 50 ms minimum

Modbus RS485 serial interface – Standard with LCD Display units

Transit time ultrasonic

400 PSI

LCD Display Units with Modbus or No-Display Units

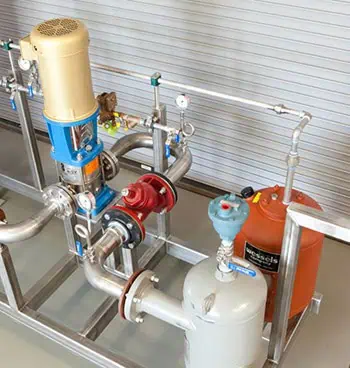

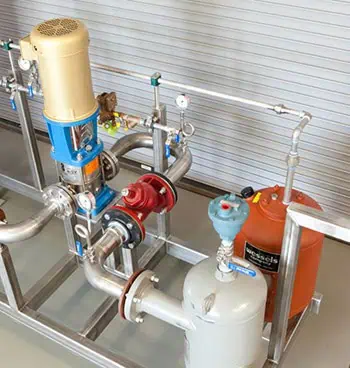

Real-World Applications

Cooling Systems

The WIN ultrasonic meter is used to measure water and water/glycol solutions in cooling systems used in HVAC systems, industrial chillers, and refrigeration.

Hydraulic Systems

WIN Water Inline Ultrasonic meters are used in hydraulic systems in aircraft and industrial machinery to provide feedback on critical hydraulic fluids that provide lubrication and corrosion resistance.

Heat Transfer Systems

Solar thermal systems, geothermal systems, and other closed-loop heat transfer applications use these ultrasonic flow meters to monitor water-glycol solutions which are essential to enhancing thermal efficiency and preventing freezing.

Marine Fuel Monitoring

The JV-BB gear meter is ideal for marine fuel monitoring due to its robust construction, ensuring durability in harsh environments. Its repeatable accuracy ensures consistent measurements, crucial for fuel management. Unlike many meters, it doesn’t require a straight run for installation, offering flexibility in the often confined spaces of marine vessels. Additionally, its ability to detect flow in both directions ensures reliable monitoring, making it perfect for comprehensive marine fuel management systems.

Cooling Systems

The WIN ultrasonic meter is used to measure water and water/glycol solutions in cooling systems used in HVAC systems, industrial chillers, and refrigeration.

Hydraulic Systems

WIN Water Inline Ultrasonic meters are used in hydraulic systems in aircraft and industrial machinery to provide feedback on critical hydraulic fluids that provide lubrication and corrosion resistance.

Heat Transfer Systems

Solar thermal systems, geothermal systems, and other closed-loop heat transfer applications use these ultrasonic flow meters to monitor water-glycol solutions which are essential to enhancing thermal efficiency and preventing freezing.

Marine Fuel Monitoring

The JV-BB gear meter is ideal for marine fuel monitoring due to its robust construction, ensuring durability in harsh environments. Its repeatable accuracy ensures consistent measurements, crucial for fuel management. Unlike many meters, it doesn’t require a straight run for installation, offering flexibility in the often confined spaces of marine vessels. Additionally, its ability to detect flow in both directions ensures reliable monitoring, making it perfect for comprehensive marine fuel management systems.