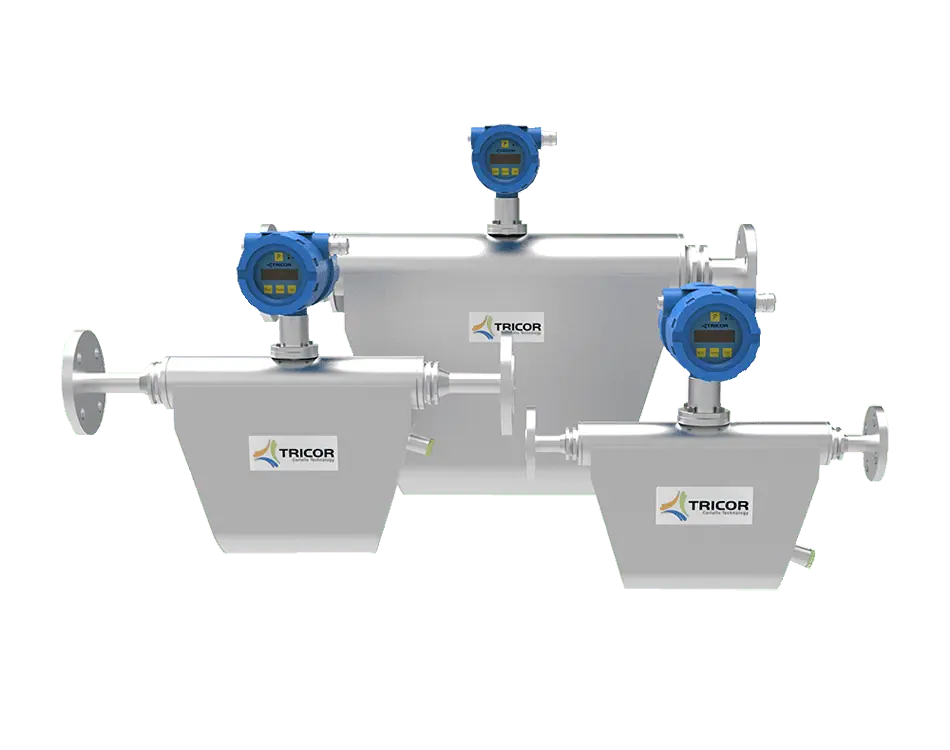

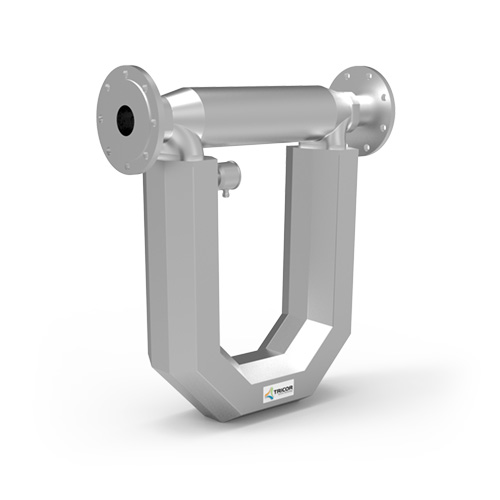

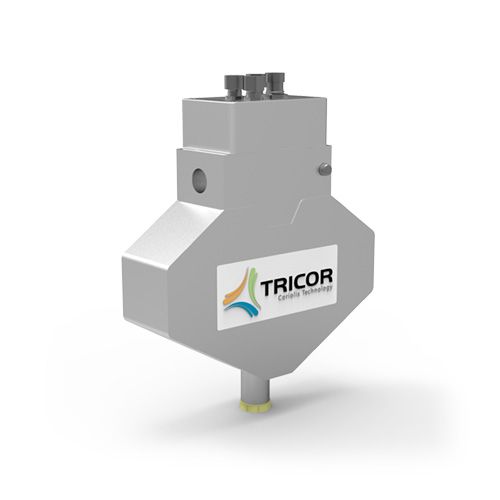

The unique design and proprietary manufacturing procedures of TRICOR Coriolis products produce perfectly balanced tubes for high accuracy, repeatability and process noise immunity. TRICOR Coriolis meters offer exceptional ease of use and fast setup time right out of the box. Our service team works with you to provide customized solutions to your real-world needs – from custom connections to pre-programmed transmitter parameters and reporting preferences. The TRICOR Coriolis family offers a broad portfolio with pricing options that scale to performance.

Features:

• Multi-variable instrument: direct independent measurement of mass flow, density and temperature with calculated volumetric flow

• API gravity output reading

• Frequency output up to 10,000 Hz resolution

• Easily accessible, integrated meter diagnostics to verify meter health & performance

• Hazardous area certifications: ATEX, IECEx, CSA, TR (EAC)

± 0.1% of flow rate

± 0.01% of full scale

± 0.05% of flow rate

TCM 0325: 325 kg/hr | 12 lbs/min | 325 l/hr | 1.43 gpm | 49 bbl/d (US)

TCM 0650: 650 kg/hr | 24 lbs/min | 650 l/hr | 2.86 gpm | 98 bbl/d (US)

TCM 1500: 1500 kg/hr | 57 lbs/min | 1500 l/hr | 6.82 gpm | 234 bbl/d (US)

TCM 3100: 3100 kg/hr | 114 lbs/min | 3100 l/hr | 13.65 gpm | 468 bbl/d (US)

TCM 5500: 5500 kg/hr | 202 lbs/min | 5500 l/hr | 24.22 gpm | 830 bbl/d (US)

TCM 7900: 7900 kg/hr | 290 lbs/min | 7900 l/hr | 34.78 gpm | 1193 bbl/d (US)

TCM 028K: 28,000 kg/hr | 1029 lbs/min | 28,000 l/hr | 123.3 gpm | 4227 bbl/d (US)

TCM 065K: 65,000 kg/hr | 2388 lbs/min | 65,000 l/hr | 286.2 gpm | 9812 bbl/d (US)

TCM 230K: 230,000 kg/hr | 8450 lbs/min | 230,000 l/hr | 1013 gpm | 34,720 bbl/d (US)

TCM 0325: 2900 psi, 200 bar

TCM 0650: 2900 psi, 200 bar

TCM 1500: 2900 psi, 200 bar

TCM 3100: 2900 psi, 200 bar

TCM 5500: 5000 psi, 345 bar

TCM 7900: 1450 psi, 100 bar

TCM 028K: 1450 psi, 100 bar

TCM 065K: 1450 psi, 100 bar

TCM 230K: 1450 psi, 100 bar

Temperature Repeatability: ±0.36°F (±0.2°C)

Temperature Accuracy: ±1.8°F ±0.5% of reading (±1°C ±0.5% of reading)

Process Temperature: Standard: -40°F to +212°F (-40°C to +100°C), Optional: -76°F to +392°F (-60°C to +200°C)

Density Range: up to 2500 kg/m³, 2.5 g/cm³

Density Accuracy: ±1.0 kg/m³, ±0.001 g/cm³

Density Repeatability: ±0.5 kg/m³, ±0.0005 g/cm³

Tubes: 1.4404 / AISI 316L Stainless Steel

Case: 1.4404 / AISI 316L Stainless Steel

For more detailed material information, see Technical Datasheet or individual product Spec Sheets.

cCSAus: Class I, Division 1: Group A, B, C, D or C, D, T2…T4

ATEX: Zone 1: Group IIC or IIB, T2…T4 | Zone 2: II 3G Ex nA IIC T2…T4 Gc

IECEx: Zone 1: Group IIC or IIB, T2…T4

EAC (TR-CU): Group IIC or IIB, T2…T4

Triple Approval:

cCSAus + ATEX + IECEx: Zone 1: Group IIC or IIB, T2…T4 and Class I, Division 1: Group A, B, C, D or C, D, T2…T4

¹ Stated flow accuracy combines the effects of repeatability, linearity and hysteresis.

TCM 0325

MASS FLOW RATE: 325 kg/h | 12 lb/min

VOLUMETRIC FLOW RATE: 325 l/h | 1.43 gpm | 49 bbl/d

NOMINAL METER SIZE: DN4 mm | 1/8″

TCM 0650

MASS FLOW RATE: 650 kg/h | 24 lb/min

VOLUMETRIC FLOW RATE: 650 l/h | 2.86 gpm | 98 bbl/d

NOMINAL METER SIZE: DN4 mm | 1/8″

TCM 1550

MASS FLOW RATE: 1550 kg/h | 57 lb/min

VOLUMETRIC FLOW RATE: 1550 l/h | 6.82 gpm | 234 bbl/d

NOMINAL METER SIZE: DN6 mm | 1/4″

TCM 3100

MASS FLOW RATE: 3100 kg/h | 114 lb/min

VOLUMETRIC FLOW RATE: 3100 l/h | 13.65 gpm | 468 bbl/d

NOMINAL METER SIZE: DN6 mm | 1/4″

TCM 5500

MASS FLOW RATE: 5500 kg/h | 202 lb/min

VOLUMETRIC FLOW RATE: 5500 l/h | 24.22 gpm | 830 bbl/d

NOMINAL METER SIZE: DN15 mm | 1/2″

TCM 7900

MASS FLOW RATE: 7900 kg/h | 290 lb/min

VOLUMETRIC FLOW RATE: 7900 l/h | 34.78 gpm | 1193 bbl/d

NOMINAL METER SIZE: DN15 mm to | 1/2″

TCM 028K

MASS FLOW RATE: 28,000 kg/h | 1029 lb/min

VOLUMETRIC FLOW RATE: 28,000 l/h | 123.3 gpm | 4227 bbl/d

NOMINAL METER SIZE: DN25 mm | 1″

TCM 065K

MASS FLOW RATE: 65,000 kg/h | 2388 lb/min

VOLUMETRIC FLOW RATE: 65,000 l/h | 286.2 gpm | 9812 bbl/d

NOMINAL METER SIZE: DN40 mm | 1-1/2″

TCM 0230K

MASS FLOW RATE: 230,000 kg/h | 8450 lb/min

VOLUMETRIC FLOW RATE: 230,000 l/h | 1013 gpm | 34,720 bbl/d

NOMINAL METER SIZE: DN80 mm | 3″

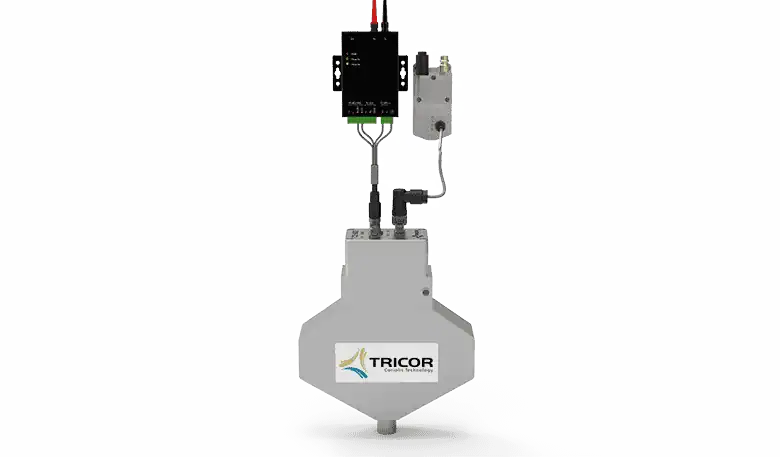

TCE 8000/8100 Compact Version

The TCE 8000 / 8100 is an economical multi-variable Coriolis

transmitter that can output flow rate, total, density or temperature.

With hazardous area approvals: ATEX, IECEx, cCSAus.

TCE 8000/8100 Wall Mount Version

Wall mounted multi-variable Coriolis transmitter that can

output flow rate, total, density or temperature.

With hazardous area approvals: ATEX, IECEx, cCSAus.

TCE 6000 Transmitter Compact Version

Multi-variable Coriolis transmitter that can output flow rate, total, density

or temperature. Ready for ESTA applications.

We can program your meter to your exact specifications, at no additional cost

Intuitive, easy-to-use interface

±0.1% of flow rate

With high performance specifications

Optional enhancement for oilfield allocation & verification

Real-World Applications

Marine Fuel Monitoring

TRICOR Coriolis flow meters are vital in marine fuel monitoring due to their precision in measuring fuel mass flow and density, ensuring accurate fuel consumption data. This accuracy is crucial for optimizing fuel efficiency, reducing operational costs, and complying with environmental regulations. Coriolis flow meters can handle the varying conditions of marine environments, providing reliable performance even with changes in temperature and pressure.

Automotive Paints & Coatings

The TRICOR Coriolis CLASSIC series flow meters are used in automotive paints and surface coating applications to improve the accuracy and reliability of dispensing. TRICOR Coriolis flow meters offer wear-free and precise measurements, including integrated density measurement to monitor the mixing ratio. This compact system provides output signals and communication via Modbus for online monitoring, ensuring effective and reliable flow measurement in the coating process.

Ratio Mixing for Resins

TRICOR Coriolis flow meters are essential in ratio mixing and blending processes, such as those used for resins, due to their ability to provide precise mass flow and density measurements for multiple liquid components. These meters ensure that each component is accurately measured and delivered in the correct proportions, which is crucial for maintaining the desired consistency and quality of the final product.

Chemical Blending and Dosing

TRICOR Coriolis flow meters are essential in chemical processing, including chemical injection systems for their precise measurement and control. These meters provide accurate mass flow and density readings, ensuring that the precise amount of chemicals is added into the process. This precision is critical for maintaining optimal chemical reactions, improving process efficiency, and reducing waste.

Marine Fuel Monitoring

TRICOR Coriolis flow meters are vital in marine fuel monitoring due to their precision in measuring fuel mass flow and density, ensuring accurate fuel consumption data. This accuracy is crucial for optimizing fuel efficiency, reducing operational costs, and complying with environmental regulations. Coriolis flow meters can handle the varying conditions of marine environments, providing reliable performance even with changes in temperature and pressure.

Automotive Paints & Coatings

The TRICOR Coriolis CLASSIC series flow meters are used in automotive paints and surface coating applications to improve the accuracy and reliability of dispensing. TRICOR Coriolis flow meters offer wear-free and precise measurements, including integrated density measurement to monitor the mixing ratio. This compact system provides output signals and communication via Modbus for online monitoring, ensuring effective and reliable flow measurement in the coating process.

Ratio Mixing for Resins

TRICOR Coriolis flow meters are essential in ratio mixing and blending processes, such as those used for resins, due to their ability to provide precise mass flow and density measurements for multiple liquid components. These meters ensure that each component is accurately measured and delivered in the correct proportions, which is crucial for maintaining the desired consistency and quality of the final product.

Chemical Blending and Dosing

TRICOR Coriolis flow meters are essential in chemical processing, including chemical injection systems for their precise measurement and control. These meters provide accurate mass flow and density readings, ensuring that the precise amount of chemicals is added into the process. This precision is critical for maintaining optimal chemical reactions, improving process efficiency, and reducing waste.

We work with you to increase process efficiency, reduce costly production down-time, establish real-time monitoring and control, and provide the critical tracking and record keeping necessary to meet EPA regulations.

Application Stories

Image Gallery